In the brewhouse unit, The malt will be boiled to get wort for fermentation and then to get the beer. The hot wort around 98℃ after boiled in kettle tun, after whirlpool, the wort will pass through heat exchanger to be cooled around 10-18℃ for different type beer. The ale type beer has higher fermentation temperature than lager beer.

The heat exchanger has single stage and double stage two types, the best brand heat exchanger is NANHUA brand in China, which has better design to maximum utilize cooling area, and its surface is SUS304 sanitary standard. It is our standard configuration at present.

The single stage HE is for cold water cooling only; and the two stage HT has city water and glycol water cooling. Here standard: The brewery capacity above 2000L will adopt single stage heat exchanger, for single stage HE, there are one Cold water tank to work together.

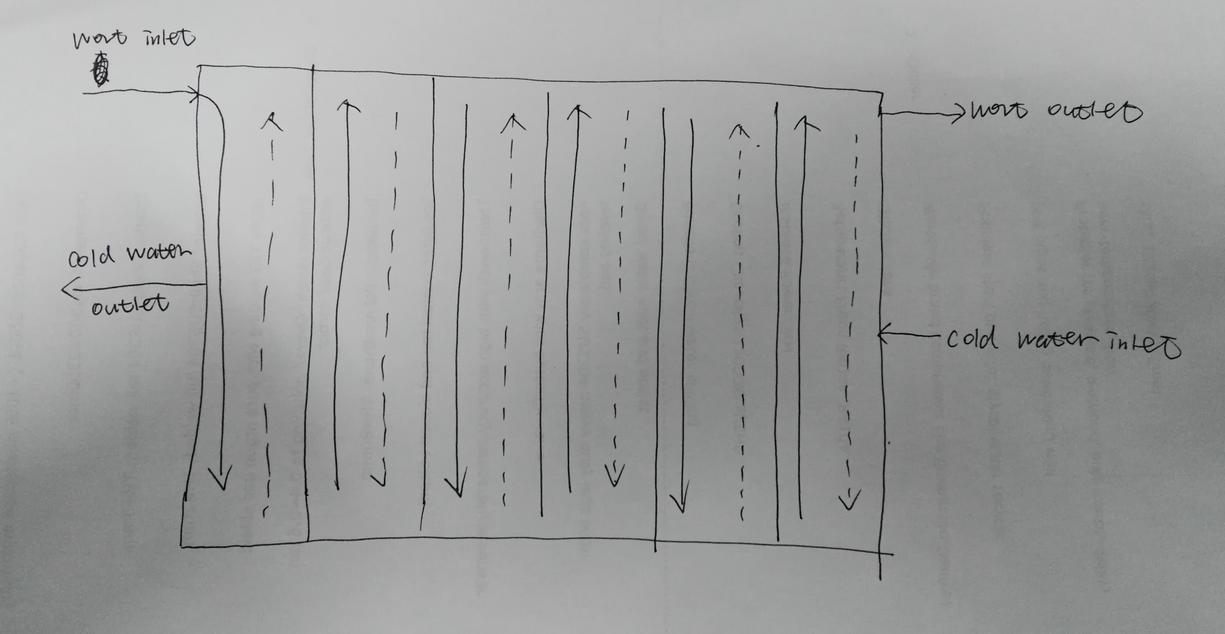

For brewery above 2000L capacity and especially brew multiple batches per day, we kindly suggest you go with single stage HE. It is because the single stage heat exchanger has good cooling function than double stage, I draw a simple drawing of single stage HE by hand, you will find there are 6 reverse flow, it has higher cooling efficiency than double stage, because there are 4 reverse flow for double stage HE.

Also with cold water cooling on HE, it is much safety for wort in case the Glycol water go into Heat exchanger.

What is your idea on the heat exchanger on your brewery?

Thank you for your reading.

Welcome you inquiry for brewery equipment.

Let’s taste one cup of Wheat beer now, -:)

Edited by Helen Lee

Sales Manager

[email protected]

.jpg)

Get In Touch