Here we are willing to explain more about the automatic water mixing station and automatic wort cooling station.

1.Automatic water mixing station

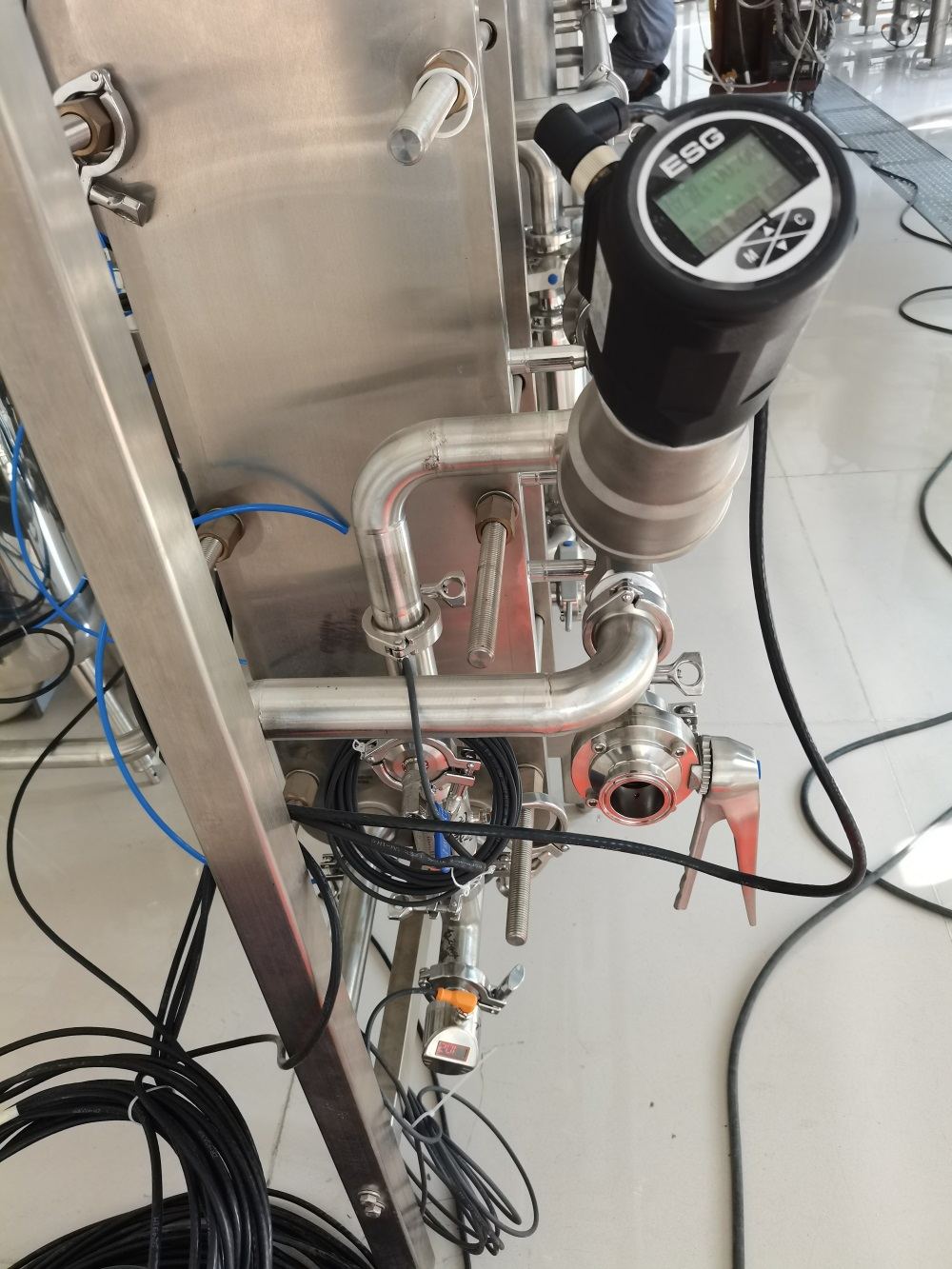

There is one pneumatic angle seat valve for hot water pipeline, and another Pneumatic angle seat valve for cold liquor pipeline.

Set-up the temperature of brewing water on the brewhouse control, when the brewhouse control got the signal from temperature sensor, the pneumatic angle seat valves will be open or closed automatically and adjust the flow rate to reach the set-up hot water temperature.

And a flow meter on the main hot water pipeline to measure the hot water capacity and flow rate.

2.Automatic Wort Cooling Station

The flow control of the glycol and water inlets and product outlet of the heat exchange based of temperatures during cooling.

For single Heat exchanger

There is Pneumatic angle seat valve on the cold water pipeline, it will adjust the cold water flow rate according to hot wort temperature.

After cooled the hot water, the cold water temperature is raised about 60℃~65℃, to recycle the hot water, then this hot water will return back to hot water tank.

After the Heat exchanger, we also equip one flow meter for wort to fermenter.

The brand of flow meter is IFM famous band.

Thanks for your reading!

Any requires about beer brewing machinery, please feel free to ask us.

Request a Proposal

Daisy

Email: [email protected]

.jpg)

Get In Touch