CIP cleaning cart is a common equipment in microbreweries to clean brewhouse, beer fementer, bright beer tank etc. Brewing tanks.

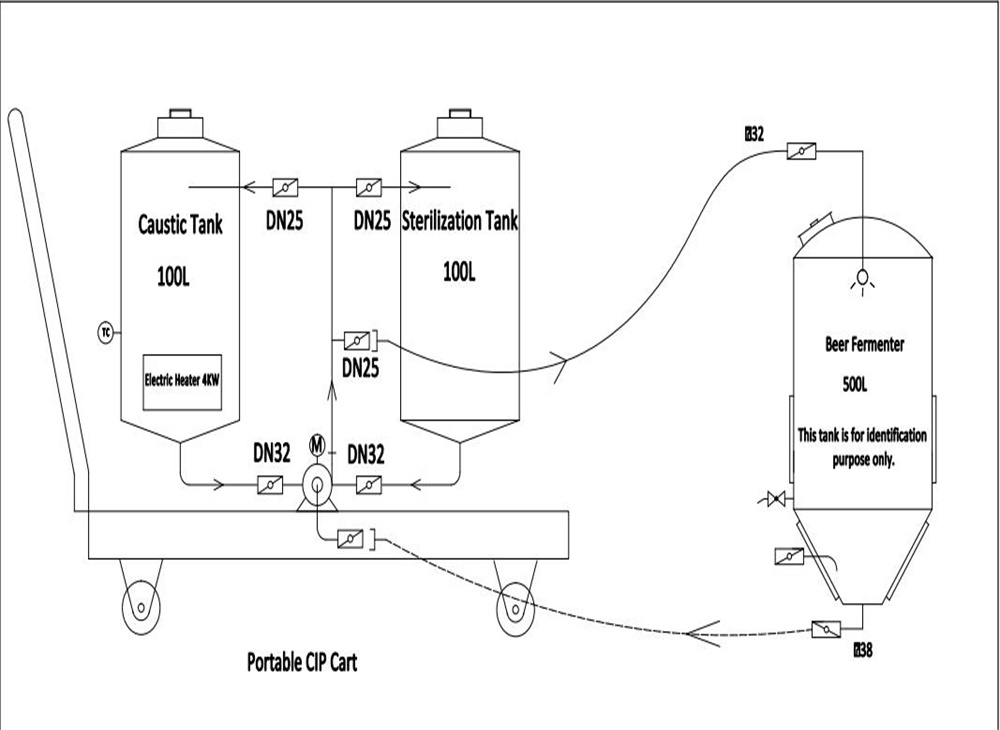

It is composed of two tanks (a caustic tank and a sterilization tank), a centrifugal pump, a

control cabinet and a portable cart.

There are clients asked us how to use it to clean the beer fermentor?

Here let’s explain the process:

Step 1: Preparing Cleaning Liquids (in an hour before cleaning)

Separately fill 100L clean city water into the caustic tank and the sterilization tank.

Then, add 5kg food grade caustic soda (sodium hydroxide) into the caustic tank to

make the concentration of caustic liquid up to 5%. And start heating by clicking the

heating button on the control panel at the same time.

Then, add about 100ml of 35% H2O2 (hydrogen peroxide) liquid into sterilization

tank to mix the liquid concentration up to 300—400PPm.

Step 2: Clean Water Washing for 15 min.

After the preparatory work, connect the CIP inlet of brewing tank with your city

water faucet by a hose. Firstly wash the brewing tanks with clean city water for 3

times and each time lasts for 3 to 5 minutes. Then, drain out the water in the tank

and leave the discharge ports open.

Step 3: Caustic Liquid Washing for 20 min.

Connect the CIP inlet of brewing tanks with the CIP pump by the flexible brewery

hoses. Keep the valves of the sterilization tank closed. Simultaneously open the

manual ball valves of caustic tank and the pump. Then, run the pump by clicking the

button and circulate the prepared hot caustic liquid in the brewing tank for lasting

15~20 min.

During this process, if the concentration of the caustic liquid becomes lighter, then

some more solid caustic needs to be added. (Pay attention to protect your eyes and

your body by wearing the protective device! Do not contact with the caustic liquid

directly.) After that, the caustic liquid needs to be recycled back to the caustic tank.

Stop running the pump and close off the valves of the caustic tank and the pump.

Step 4: Clean Water Washing for 15min.

Repeat Step 2 to wash the brewing tank for another 3 times and each time lasts for 3

to 5 min to make sure all the caustic liquid are drained out.

Step 5: Sterilization Liquid Washing for 20 min.

Keep the valves of the caustic tank closed. Simultaneously open the manual ball

valves of sterilization tank and the pump. Then, run the pump and circulate the

prepared H2O2 liquid to wash the brewing tank for 15~20 min.

Stop running the pump and turn off the valves of the sterilization tank.

After cleaning, please turn off all the valves of the brewing tanks so as to avoid any

contamination.

ATTENTION!

1. Before use, please check the parameters of the centrifugal pump to meet your

local power supply.

2. Make sure the rotation direction of the pump is consistent with the notice on the

pump.

3. Make sure the liquid level in the caustic tank is always higher than the heating

tube to avoid any dry-burning, although there is a dry burning-resistant protection

device on the control.

4. It is not allowed to use hypochlorous acid, chlorine and anything contained with

chloridion to wash the brewing tanks.

5. Wear the necessary protective device to protect eyes and body during the process

of operation.

Request a Proposal

Daisy Cai

Email: [email protected]

.jpg)

Get In Touch