Before miller, the malt usually be packaged in bags, and feed into miller hopper manually. It is the most common operation for microbrewery.there are few microbrewery adopt automation malt feeding system(will not expand here).

For microbrewery, There are different configurations on malt milling solution.

1. Malt miller

It is simple. The malt will be crushed by miller and fall into a bag/container ,and then feed into mash tun manually.

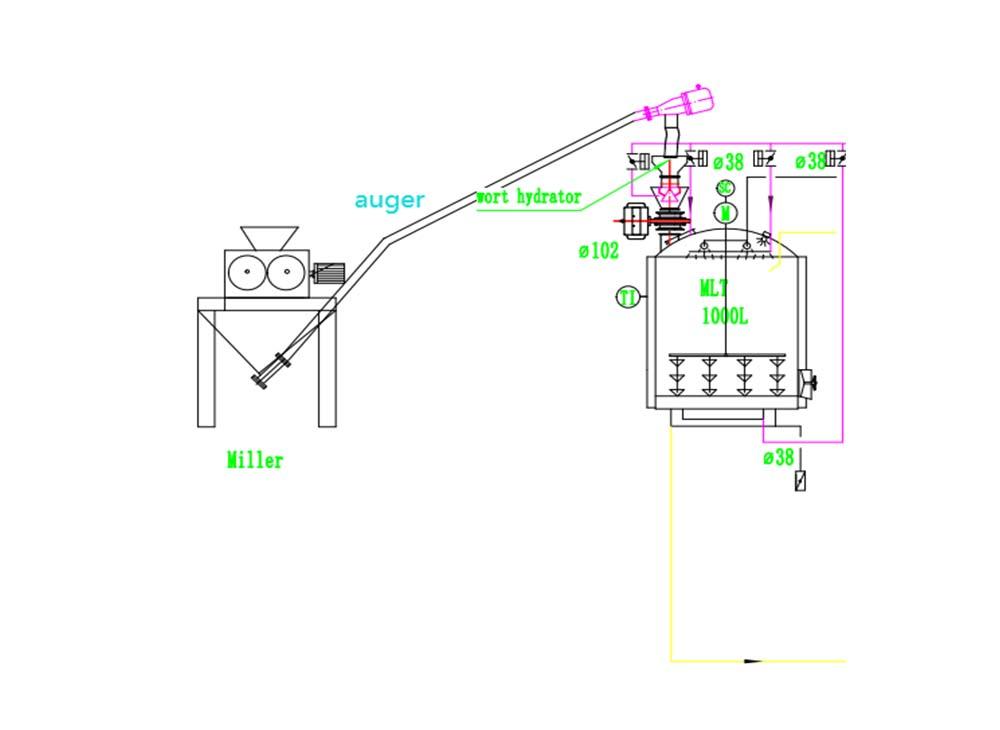

2. Malt miller+flexible auger+grist hydrator at top of MT

The miller is modified to be with a hopper at bottom for dust proof, and the outer will be connected with auger, the other end of auger will connect with hydrator. In this case, the customer location usually have height limitation, so there is no grist silo for store crushed malt. See the reference drawing as below.

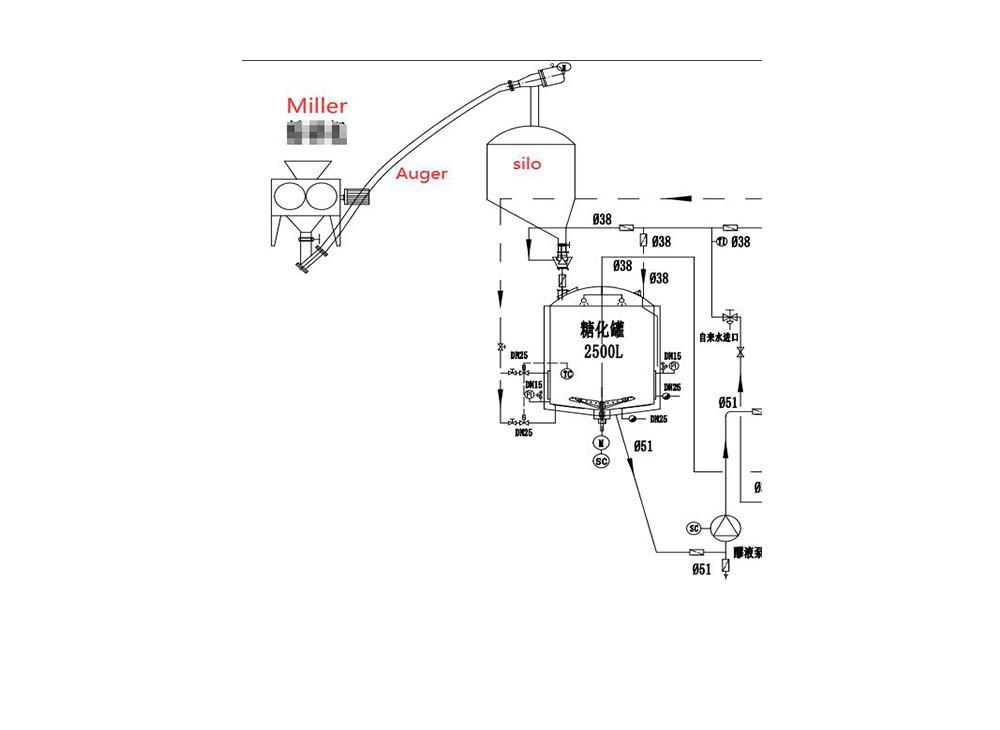

3. Malt miller+flexible auger+grist silo+grist hydrator at top of MT

This case include grist silo than the above solution.

It happens when customer location height is enough ,also budget is sufficient.

This solution is commonly for brewery above 2000L.

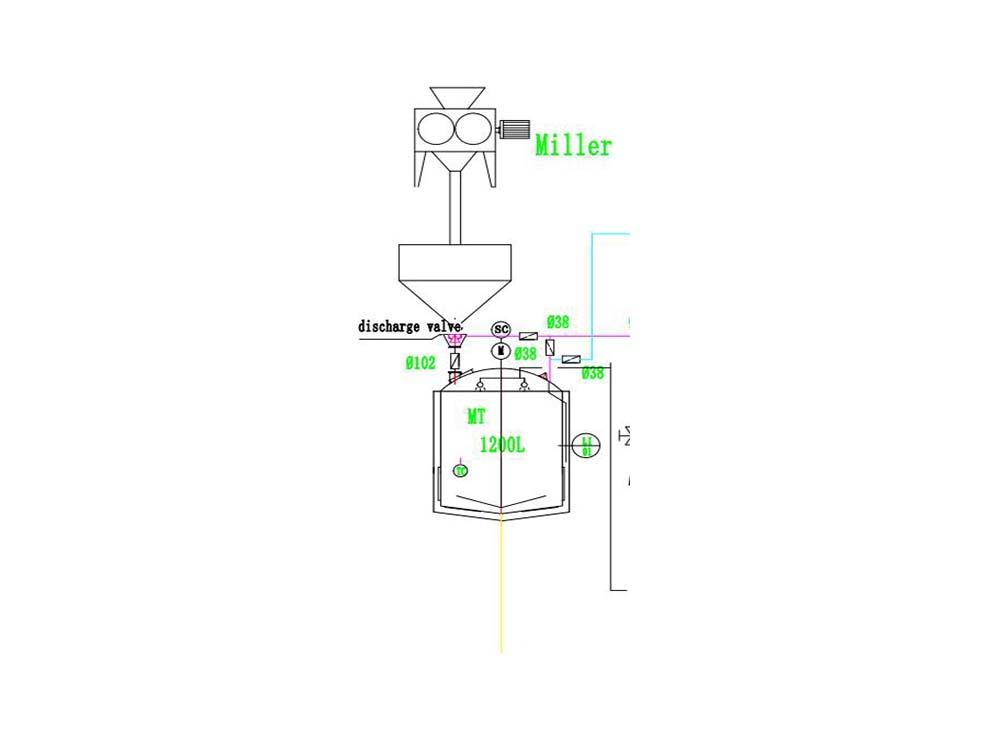

4. Malt miller+grist silo+grist hydrator at top of MT

This case, the miller will be placed at the first floor. The customer will drill a hole on the floor, and crushed malt will fall into the grist silo by gravity. The grist silo usually be build with cone at the middle bottom, not eccentric cone.

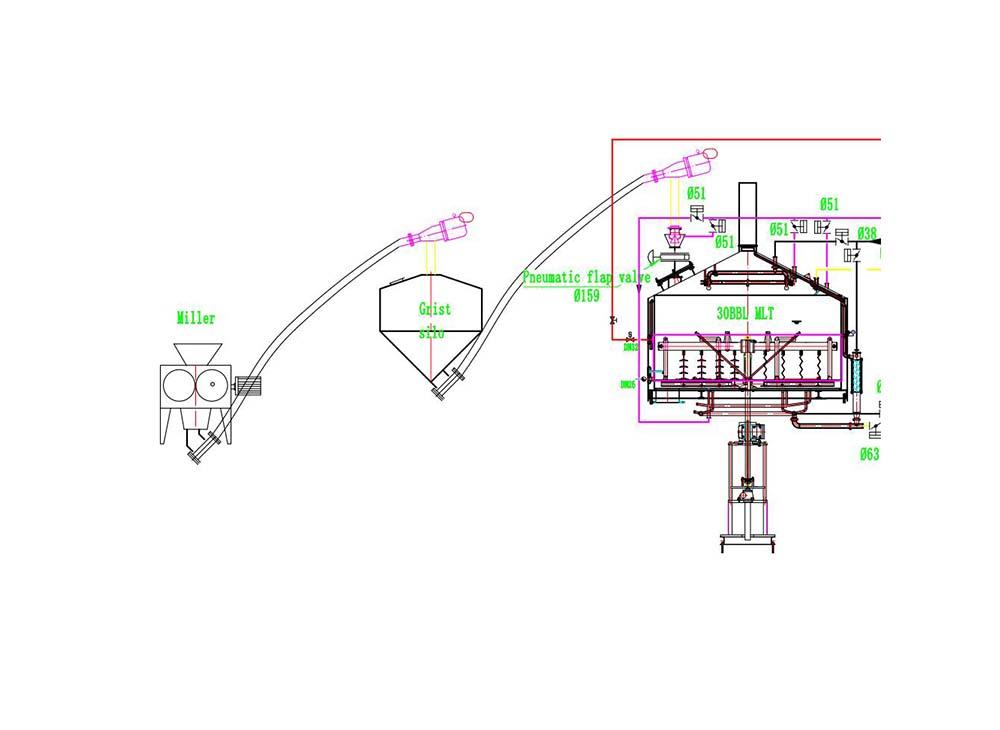

5. Malt miller+ auger+grist silo+ auger+grist hydrator at top of MT

This case is available when the ceiling height is not enough,and customer don’t want to transfer crushed malt by manual.

If you could send us your brewery location floorplan, we could design the suitable milling solution for you. Of course, there is also customer buy crushed malt directly at present. It is convenient, but it also bring restrictions when you plan to brewing some special beers.

If you have different idea on milling solution, feel free to contact us .we could discuss together. We not only provide malt milling solution, our advantage is complete brewery equipment solution.

Tiantai Brewtech is one professional brewery equipment manufacturer in China, with more than 19 years experience on micro brewery equipment designing,manufacturing, have built more than 1800 craft beer brewery plant in the world. We hope to work with you together to build fantastic brewery plant for you.

Thank you so much for your reading.

Helen Lee

[email protected]

.jpg)

Get In Touch