Normally malt crushing can be used by dry method or wet method, but it have certain

apply range.

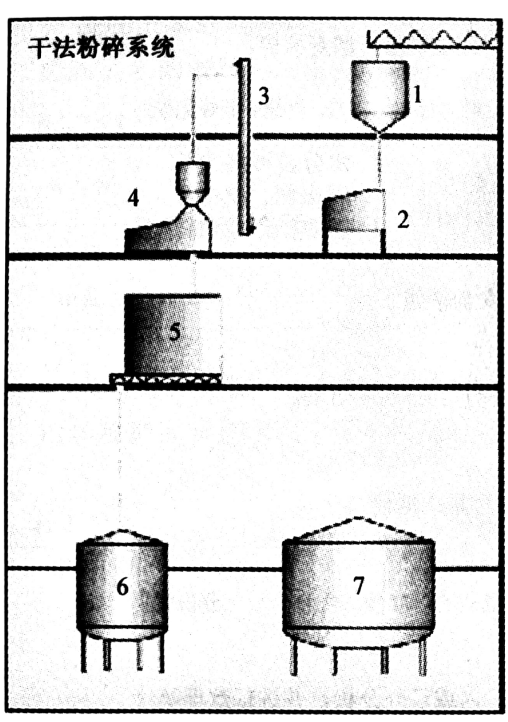

Malt crushing by dry method is one traditional way, which have simple configuration

and easy operating. It is a widely use malt crushing method in middle/micro microbrewery.

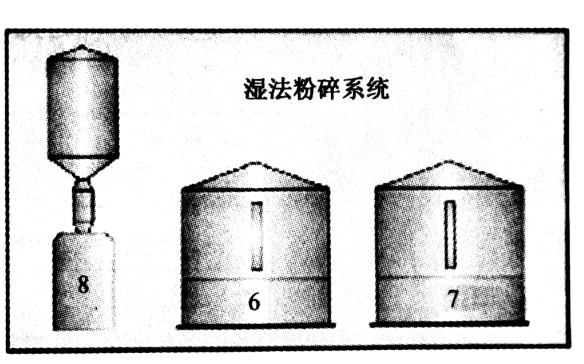

For most industrial brewery, malt crushing by wet method is chosen. And wet milling is

very common in Africa and Asia, as it simplifies the grinding. In this situation, the malt

need soak in the hot water about 15-20 minutes, which can make malt water content

reach to 30% and malt tenacity also increase, thus malt husk can keep complete.

Also the spent grain in loosen situation and speeding lauter process, as well as reduce

harmful components leach, no dust.

Here is a comparison for these 2 method.

| Dry crushing | Wet crushing | |

| Advantages |

1. Easy operation, lower current consuming. 2. Dry endosperm to reach to good milling result. 4. Drier milled malt have a long storage time. 5. The skin and endosperm could be separated well. |

1. Milling room can be shared together with brewhouse room. Lower budget. 2. No need crushed malt hopper to save cost. 3. Milling and mashing process can be continuously operated. 4. Husk is intact and tough to reach a good filter effect. 5. Little dust pollution. 6. The unit area loading of false bottom is bigger, 250-350kg/m2. |

| Disadvantages |

1. Milling room must be separated with brewhouse room. Higher budget. 2. Need crushed malt hopper. 3. Tannic is easy to be extracted to make wort in darker color and bitter taste. 4. More dust, with a risk of explosion. 5. The unit area loading of false bottom is smaller, 190kg/m2. |

1. Wet milled malt have a short storage time. 2. Mashing yield is 2% lower than dry milling. 3. Clean miller everything after using, it increases the labor more or less. 4. It needs higher sanitary level to avoid bacterial infection. |

| Flow chart |

|

|

| 1. Grain Silo 2. Stoner gravity separation 3. Bucket Elevator Conveyor 4. Dry Miller 5. Crushed Grain Hopper 6. Cooking Tun 7. Mash Tun 8. Wet Miller | ||

Edited by Emily

Sales Manager in Tiantai Company

Email: [email protected]

.jpg)

Get In Touch