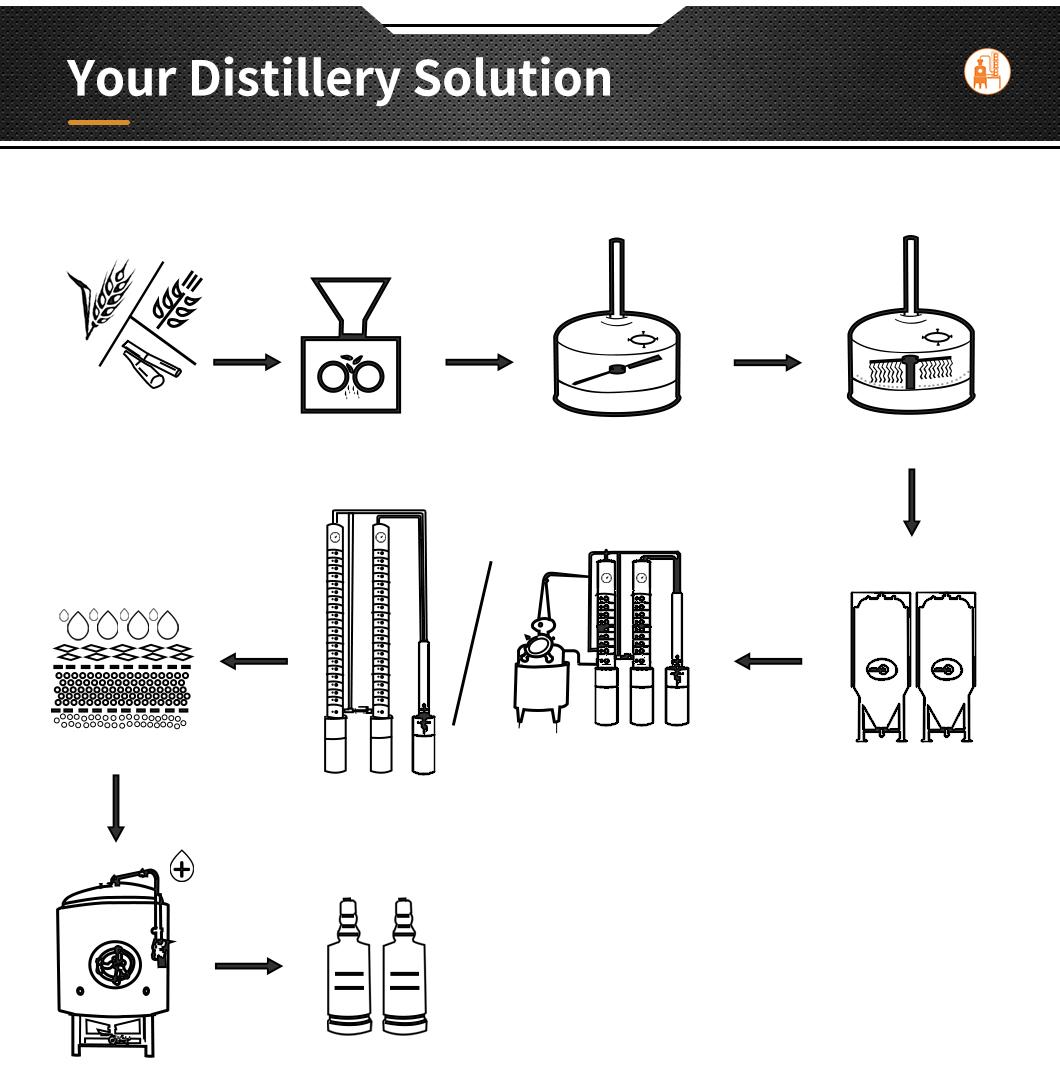

Grain whisky, a distinct and essential component in many famous blends and single malt expressions, is cherished for its smooth character and subtle flavors. While brewing grain whisky may seem like a complex and industrial process, it all starts with understanding the right equipment needed for production. This article explores in detail the various pieces of equipment required to brew grain whisky, guiding both home distillers and large-scale producers through the essentials.

1. Mash Tun

The mash tun is a critical piece of equipment used to extract fermentable sugars from the grains. It is essentially a large vessel, typically made of stainless steel or copper, equipped with an internal heating system and a false bottom to separate the liquid wort from the spent grains. The mash tun allows hot water to mix with crushed grains, enabling the enzymatic conversion of starches into sugars.

Key features:

Insulation to maintain a consistent temperature.

A sparging system for efficient rinsing of grains.

A drainage system to collect the wort.

For larger operations, mash tuns may come with automated temperature controls, while home brewers may use a simpler, manually operated version.

2. Grist Mill

Before mashing can begin, the grains need to be crushed, which is done using a grist mill. The goal is to break open the grains while preserving the husk, which aids in the filtration process during mashing.

Types of grist mills:

Roller mills: These are common in commercial distilleries and allow precise control over the grain crush.

Hammer mills: Often used for finer grinding, which can improve extraction but requires careful handling.

Homebrew mills: Smaller, hand-cranked mills are available for hobbyists.

Choosing the right mill and properly adjusting the grind size is crucial to ensure efficient mashing and sugar extraction.

3. Lauter Tun

The lauter tun is used to separate the wort from the grain solids after mashing. It typically contains a slotted or perforated bottom that allows the liquid to pass through while retaining the spent grains.

Features to consider:

Raking mechanisms to prevent clogging and improve wort flow.

A sparge arm to distribute water evenly over the grains for maximum sugar extraction.

For smaller-scale production, the mash tun may double as a lauter tun, while in larger operations, these are separate, specialized vessels.

4. Fermentation Tanks

Once the wort is collected, it is transferred to fermentation tanks where yeast is added to begin the fermentation process. Fermentation tanks come in various sizes and materials, with stainless steel being the most common due to its durability and ease of cleaning.

Features of fermentation tanks:

Temperature control to maintain the ideal fermentation temperature.

Airlocks to allow carbon dioxide to escape while preventing contamination.

Agitation systems in larger tanks to ensure even fermentation.

For traditional methods, wooden washbacks (fermentation tanks made of oak or other wood) are sometimes used, imparting unique flavors to the whisky.

5. Distillation Equipment

Distillation is the core process that transforms the fermented wash into high-proof whisky. Grain whisky is typically distilled using a column still, also known as a continuous or Coffey still, rather than the pot stills used for malt whisky.

Key components of a column still:

Analyzer column: This is where the wash enters and is heated, causing alcohol and volatile compounds to vaporize.

Rectifier column: The vapor rises through a series of plates or trays, where it condenses and re-vaporizes, effectively increasing the alcohol concentration.

Condenser: This cools the alcohol vapor, turning it back into liquid.

Column stills offer several advantages over pot stills, including continuous operation and a higher level of efficiency. Home distillers, however, may opt for smaller, manually operated pot stills.

6. Cooling System

A cooling system is essential during the distillation process to condense the alcohol vapor back into liquid form. Common cooling methods include:

Shell and tube condensers: Used in larger operations, where water flows through tubes surrounded by the vapor.

Worm tubs: Traditional systems where the vapor passes through a coiled pipe submerged in a water bath.

Efficient cooling ensures that the distillate is collected at the right strength and purity.

7. Storage and Aging Barrels

Grain whisky must be aged in oak barrels to develop its flavor and character. The barrels are typically made from American oak or European oak, each imparting unique notes to the whisky.

Barrel selection considerations:

New vs. used barrels: Used barrels, such as those previously used for bourbon, are commonly employed in whisky production.

Toasting and charring levels: These affect the flavor profile, with higher levels of char contributing more vanilla and caramel notes.

Barrels must be stored in a cool, humid environment to allow the whisky to mature gradually over several years.

8. Pumps and Piping

Pumps and piping systems are essential for transferring liquid between different stages of the brewing process. These systems must be made of food-grade materials to prevent contamination and should be designed for easy cleaning.

Types of pumps:

Centrifugal pumps: Common in large distilleries for high-volume transfers.

Peristaltic pumps: Often used for more delicate transfers to avoid damaging the liquid.

Properly designed piping minimizes dead zones where residues can accumulate, ensuring cleanliness and efficiency.

9. Filtration Systems

Filtration is necessary at various stages to remove unwanted solids and impurities from the whisky. Common filtration methods include:

Plate and frame filters: Used to clarify the wort before fermentation.

Activated carbon filters: Employed after distillation to remove unwanted congeners.

Polishing filters: Used before bottling to ensure a clear, bright appearance.

10. Bottling Equipment

Once the whisky has matured and been blended (if necessary), it is ready for bottling.

Bottling equipment can range from simple manual fillers to fully automated systems that include:

Bottle rinsers.

Filling machines.

Capping and sealing machines.

Labeling machines.

Proper bottling ensures that the whisky maintains its quality and appearance from distillery to consumer.

11. Cleaning and Sanitation Equipment

Maintaining cleanliness is vital in whisky production to prevent contamination and ensure product consistency. Cleaning and sanitation equipment includes:

CIP (Clean-in-Place) systems: Used in larger distilleries to clean tanks and piping without disassembly.

Steam generators: Employed for sanitizing equipment.

Chemical cleaning agents: Specifically formulated for brewing equipment.

12. Quality Control Instruments

Quality control is essential at every stage of whisky production. Important instruments include:

Hydrometers and refractometers: To measure sugar content and alcohol strength.

pH meters: For monitoring the acidity of the mash and fermenting wash.

Thermometers: To ensure proper temperature control during mashing, fermentation, and distillation.

Gas chromatographs: Used in advanced distilleries to analyze the chemical composition of the whisky.

Brewing grain whisky requires a range of specialized equipment, each playing a critical role in ensuring the final product meets the desired standards of flavor, aroma, and quality. Whether you are a home enthusiast experimenting with small batches or a commercial producer aiming for large-scale production, investing in the right equipment is essential. By understanding the function and importance of each piece of equipment, you can create a whisky that stands out in both character and craftsmanship.

Mash tun, fermentation tank, cooling system, Whisky distillery equipment, CIP system, control system are all needed for grain whisky distillery.

If you are interested in any beer brewery equipment, please feel free to contact us:

Ivy Liang(Sales Director)

Email: [email protected]

.jpg)

.jpg)

.jpg)

Get In Touch