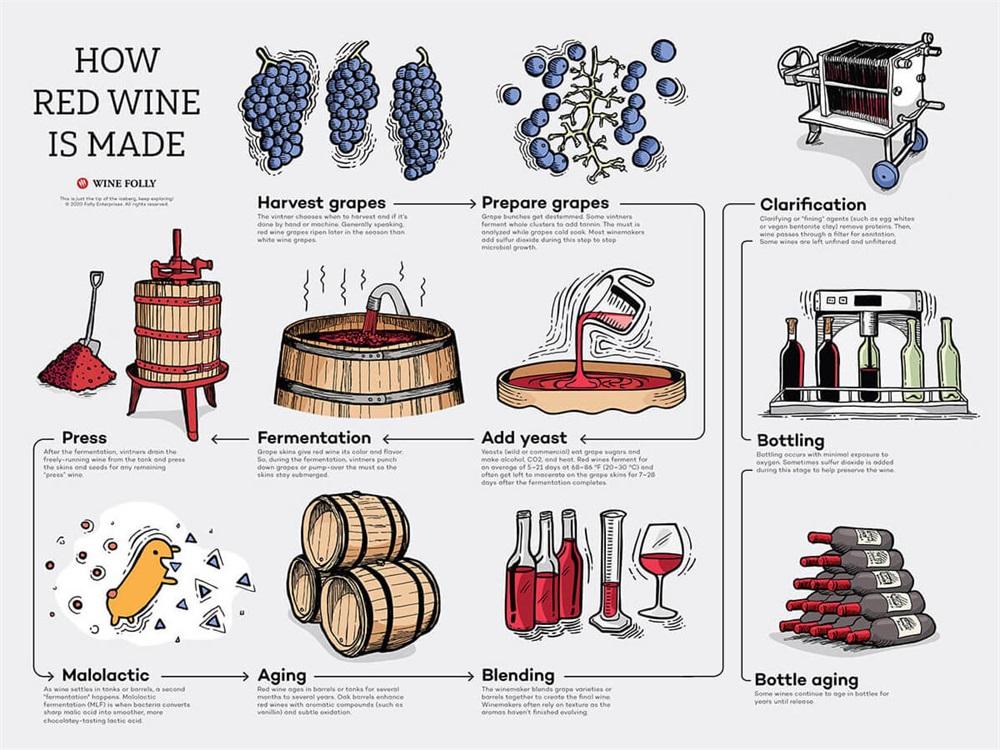

The process of fermentation in wine making turns grape juice into an alcoholic beverage. During fermentation, yeasts transform sugars present in the juice into ethanol and carbon dioxide (as a by-product). In wine making, the temperature and speed of fermentation are important considerations as well as the levels of oxygen present in the must at the start of the fermentation. The risk of stuck fermentation and the development of several wine faults can also occur during this stage, which can last anywhere from 5 to 14 days for primary fermentation and potentially another 5 to 10 days for a secondary fermentation. Fermentation may be done in stainless steel tanks, which is common with many white wines like Riesling, in an open wooden vat, inside a wine barrel and inside the wine bottle itself as in the production of many sparkling wines.

During fermentation, there are several factors that winemakers take into consideration, with the most influential to ethanol production being sugar content in the must, the yeast strain used, and the fermentation temperature. The biochemical process of fermentation itself creates a lot of residual heat which can take the must out of the ideal temperature range for the wine. Typically, white wine is fermented between 18-20 °C (64-68 °F) though a wine maker may choose to use a higher temperature to bring out some of the complexity of the wine. Red wine is typically fermented at higher temperatures up to 29 °C (85 °F). Fermentation at higher temperatures may have adverse effect on the wine in stunning the yeast to inactivity and even "boiling off" some of the flavors of the wines. Some winemakers may ferment their red wines at cooler temperatures, more typical of white wines, in order to bring out more fruit flavors.

To control the heat generated during fermentation, the winemaker must choose a suitable vessel size or else use a cooling device. Various kinds of cooling devices are available, ranging from the ancient Bordeaux practice of placing the fermentation vat atop blocks of ice to sophisticated fermentation tanks that have built-in cooling rings.

A risk factor involved with fermentation is the development of chemical residue and spoilage which can be corrected with the addition of sulfur dioxide (SO2), although excess SO2 can lead to a wine fault. A winemaker who wishes to make a wine with high levels of residual sugar (like a dessert wine) may stop fermentation early either by dropping the temperature of the must to stun the yeast or by adding a high level of alcohol (like brandy) to the must to kill off the yeast and create a fortified wine.

The ethanol produced through fermentation acts as an important co-solvent to the non-polar compound that water cannot dissolve, such as pigments from grape skins, giving wine varieties their distinct color, and other aromatics. Ethanol and the acidity of wine act as an inhibitor to bacterial growth, allowing wine to be safely kept for years in the absence of air.

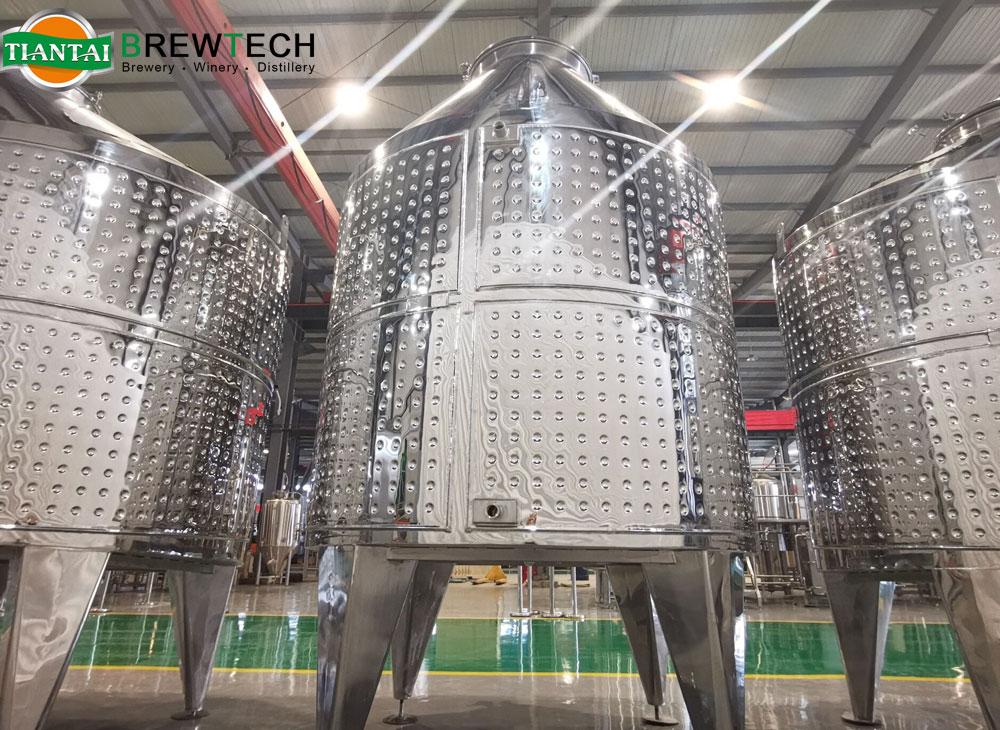

2.TIANTAI Your Trusted Source for Winery, Cider Equipment & Supplies

At Tiantai we provide an exceptional selection of equipment and supplies at competitive prices from some of the best manufacturers from around the world. We are a Direct Distributor for almost everything we sell which aids us in our ability to provide unparalleled service and support. In addition to providing great products and service we enjoy and embrace the exchange of new ideas, trends and technology with others who share our enthusiasm and desire to grow and develop our industries.

3. Features of TIANTAI Wine Equipment

Our Professional Closed Top Jacketed Conical Bottom (White Wine) Tanks are constructed entirely of AISI 304 Stainless Steel, are built to our specifications and come standard with the following features:

-Conical Bottom

-Welded "Honeycomb" Jacket(s)

-Hinged Lid / Top Door with Vent & Airlock

-Total Drain Port with Tri-Clamp Ball Valve

-Partial Drain Port with Tri-Clamp Ball Valve

-Lower Agitator Port with Tri-Clamp Ball Valve

-Top Clean In Place Port with Tri-Clamp End/Seal Cap

-Sample Port with Valve & Tap

-Manway Door

-Ladder Rack and Top-welded Lifting Rings

-Welded Legs

-Sight Level Gauge

-Thermometer and Thermowell

4.TIANTAI Quality Features:

Full Jacket - Equipped with a jacket that covers all accessible areas of the tank and is designed for an operating pressure of 2.5 to 6 bar. This will allow you to hook it into a glycol system for complete temperature control!

Interior Finish - TIANTAI tanks feature an ultra-smooth 2R rated interior surface which effectively resists the build-up of tartrate residues. Clean your tanks with cold water after cold stabilization! Say goodbye to harsh cleaning chemicals and expensive CIP systems!

Weld Quality - TIANTAI’s robotic-arm laser welders create flawless stainless to stainless junctions that look and feel more like a taped fabric seam than a traditional weld. Ultra high-quality welds leave no chance for residual product to harbor spoilage organisms.

Thickness - TIANTAI tanks are designed to be the correct thickness for the tank's total volume.

Complete Drainage Bottoms - All TIANTAI tanks are outfitted with conical, pocketed bottoms for total drainage, which maximizes product yield at rackings and makes cleaning a snap.

Please note that smaller, flat-bottomed tanks do not feature total drainage bottoms.

Tri-Clamp Valve Ferrules - All TIANTAI tanks come configured for use with Tri-Clamp (TC) style valves and fittings. Tanks up to 1600L capacity are outfitted for use with 1.5 in TC. Other sizes and custom configurations are available at additional cost upon request.

Please Note: TC valves not included. Please inquire with your sales associate for pricing on TC valves and fittings.

Rubber Lid Gaskets - Rubber gaskets are much thicker than the traditional clear vinyl gaskets, which along with their extruded manufacturing process provide a much better seal with the tanks wall. They're seamless and more oxygen resistant than the clear gaskets. That means better protection for your wines!

Warranty - TIANTAI each and every tank with an industry-leading 10 year warranty against defects in materials or workmanship. And, as a 5th generation manufacturer, you can be confident they'll be around to honor that warranty should the need arise.

.jpg)

.jpg)

Get In Touch