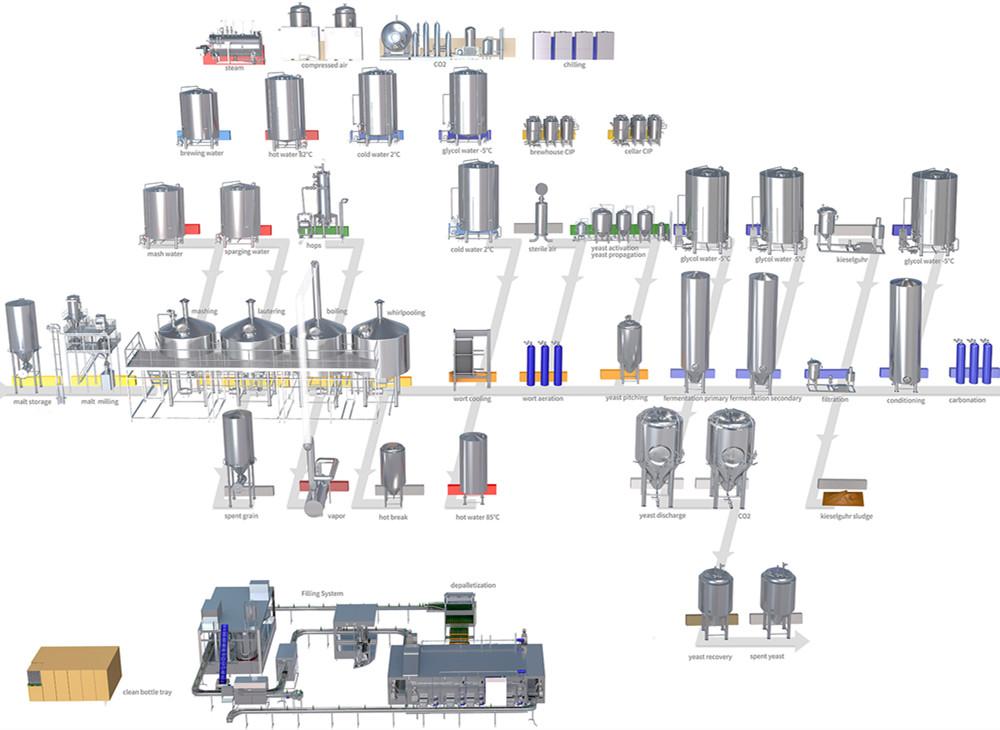

A brewery plant with an annual output of 40 million liters is a mass production brewery that produces approximately 80 to 100 million bottles of bottled beer annually. This type of brewery equipment can not only meet the large-scale brewing needs of popular beers such as lager, but can also adapt to the production of various specialty craft beers to meet the unique requirements of different consumer markets.

.jpg)

The brewery packaging options include glass bottles, cans, kegs, and PET bottles. These are distributed to various outlets, such as supermarkets, restaurants, bars, and pubs.

It is recommended that breweries be located as close to the market as possible to reduce supply distances, simplify logistics, and guarantee the freshness of the beer.

| Annual total | 40 million liters |

| Annual maximal | 60 million liters |

| Brewhouse output per batch | 15000 liters |

| Cellar capacity | >3000000 liters |

| Annual filling capacity | 50 million liters |

Tiantai designs the layout according to your site and conducts beer process design to improve site utilization and save energy for you.

From production to packaging, Tiantai has you covered with malt millers, customized brewhouses, fermentation tanks, filling lines, and more brewery equipment.

.jpg)

|

Ingredients Storage System – Steel silo *2-6 units – Bucket elevator *2-3 units – En-Masse Conveyor *2 units – Operating Platform *1 set .jpg) |

|

Malt Milling System – Bucket elevator *2 units – Gravity destoner *1 unit – Permanent magnet drum *1unit – Wet mills *1 unit – Pulse dust collector *1 set – Operating Platform *1 set .jpg) |

|

Brewhouse System – Mash tun *1 unit – Lauter tun *1 unit – Cereal cooker *1 unit – Brew kettle *1 unit – Whirlpool tank *1 unit – Plate and frame heat exchanger *1 unit – Wort aeration system *1 set – Yeast pitching system *1 set – Supporting pumps, valves, sanitary stainless steel pipes, various sensors, operating platforms, etc. .jpg) |

|

Fermentation System – 200HL fermenter *5 units – 300HL fermenter *8 units – 600HL fermenter *15 units – Supporting pumps, valves, sanitary stainless steel pipes, various sensors, operating platforms, etc. .jpg) |

|

Filtration System – Disc centrifuges *1 unit – Buffer tank *1 unit (According to process design) – Kieselguhr adding tank *1 unit – Front buffer tank *1 unit – Kieselguhr mixing tank *1 unit – Candle filter *1 unit – Rear buffer tank *1 unit – Bag trap *1 unit – Other adding systems are equipped according to the process – Supporting pumps, valves, sanitary stainless steel pipes, various sensors, operating platforms, etc. .jpg) |

|

Maturation and Conditioning – 200HL bright beer tank *2 units – 300HL bright beer tank *2 units – Supporting pumps, valves, sanitary stainless steel pipes, various sensors, operating platforms, etc. |

|

Pasteurization System – Flash pasteurizer *1 unit – Buffer tank *1 unit – Supporting pumps, valves, sanitary stainless steel pipes, various sensors, operating platforms, etc. |

|

Control System – MCC cabinet *1-4 sets – PC operator station *1 set – Operation system *1 set – Brewing program *1 set |

|

CIP System – Hot alkali tank *2 units – Cold alkali tank *2 units – Acid tank *2 units – Disinfectant tank *2 units – Hot water tank (sterile water tank) *2 units – Supporting pumps, valves, sanitary stainless steel pipes, various sensors, etc. |

|

Hot Water Supply – Hot liquor tank *1unit – Heat exchanger *1 unit – Supporting pumps, valves, sanitary stainless steel pipes, various sensors, etc. |

|

Cold Water Supply – Cold liquor tank *1 unit – Heat exchanger *1 unit – Supporting pumps, valves, sanitary stainless steel pipes, various sensors, etc. |

|

Brewing Water Supply – Brewing water tank *1 unit – Supporting pumps, valves, sanitary stainless steel pipes, various sensors, etc. |

|

Refrigeration System – Chiller *2 units – Glycol water tank *1 unit – Cooling tower *1 unit (According to process design) – Supporting pumps, valves, sanitary stainless steel pipes, various sensors, etc. .jpg) |

|

Water Deaeration Systems – Deoxygenation tower *1 unit – Deoxygenated water storage tank *1 unit – Supporting pumps, valves, sanitary stainless steel pipes, various sensors, etc. .jpg) |

|

Reverse Osmosis System – Raw water tank *1 unit – RO water treatment machine *1 unit – Supporting pumps, valves, sanitary stainless steel pipes, various sensors, etc. |

|

Steam Supply System – Steam boiler *1-2 units – Distributor *several sets – Condensate tank *1 unit – Energy storage tank *1 unit – Steam pipes, valves, etc .jpg) |

|

Compressed Air Supply System – Oil-free air compressors *2 sets – Air buffer tank *1 sets – Air dryer *1 sets – Several filters – Supporting pumps, valves, etc.  |

|

CO2 Supply System – Liquid CO2 storage tank *1 unit – Gasifier *1 unit – Pressure regulating station *1 set – Buffer tank *1 unit – Supporting pumps, valves, sanitary stainless steel pipes, detection sensors, etc. .jpg) |

|

Electricity Supply System – Power cables – Signal communication cables – Cable bridge – Bridge bracket – Conduit .jpg) |

|

High-Gravity Dilution System – Raw water flow automatic control system – Dilution water preparation system – Deoxygenated water level control unit – Deoxygenated water carbonation unit – Deoxygenated water cooling unit – Deoxygenated water secondary mixing unit – Deoxygenated water buffer unit – CIP unit – PID volume control system – PLC electronic control system – Supporting pumps, valves, sanitary stainless steel pipes, detection sensors, etc. |

|

Filling System (bottle) – Depalletizer *1 set – Rinsing machine *1 unit – Filling machine *1 unit – Capper machine *1 unit – Tunnel pasteurizer *1 unit – Drying Machine *1 unit – Labelling Machine *1 unit – Inspection Machine *1 unit – Packaging Line *1 set – Palletizer *1 set .jpg) |

Reference Projects

From annual 10 to 100 million liters capacity, we help you achieve a sustainable brewing future with innovative and efficient solutions.

.jpg)

.jpg)

.jpg)

Our service process

From product testing to maintenance 10 years down the road, we are a single point of responsibility with in-house engineering, fabrication, and service.

Study/Costing

We provide you with competent and consistent support during the evaluation of your investment.

Technical Support

We offer: 2D/3D drawings, Layout plan, Interactions with civil engineering work.

Manufacturing

Using modern manufacturing techniques, we produce precise, high quality stainless steel tanks.

On-site Installation

Tiantai has professional civil and mechanical piping staff, who provide you with on-site guidance and information about their project type.

Training

Our training for you: Operator training, Maintenance training, Automation training, Individual training for your specific needs

Optimization

If you have equipment that needs upgrades or retrofitting, we can help you analyze its performance and identify areas for improvement.

Spare Parts

No down-time, only on-time.The parts you order from us are the exact same or better than those already installed in your equipment.

Maintenance

At Tiantai, we offer a remote assistance service that allows our technicians to interact with operators remotely.

.jpg)

Have questions about setting up a brewery? Let’s talk about how we can help you.and take your business to the top!

Our team of experts is always available to assist you. Tiantai is dedicated to providing excellent customer service and ensuring your satisfaction with our products and services.

Helen Lee

Sales Manager

beerbrew@cnbrewery.com

.jpg)

Get In Touch