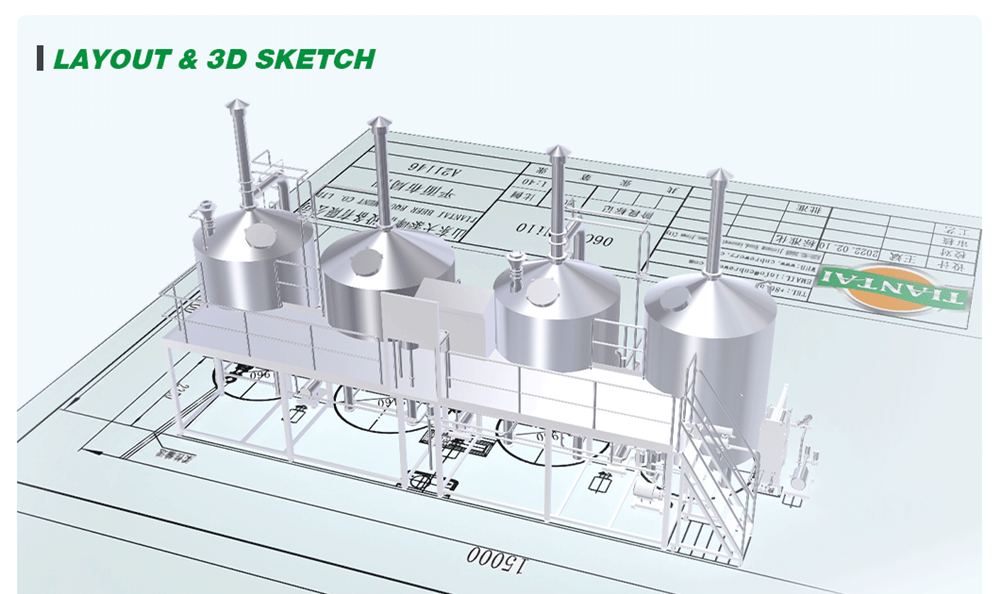

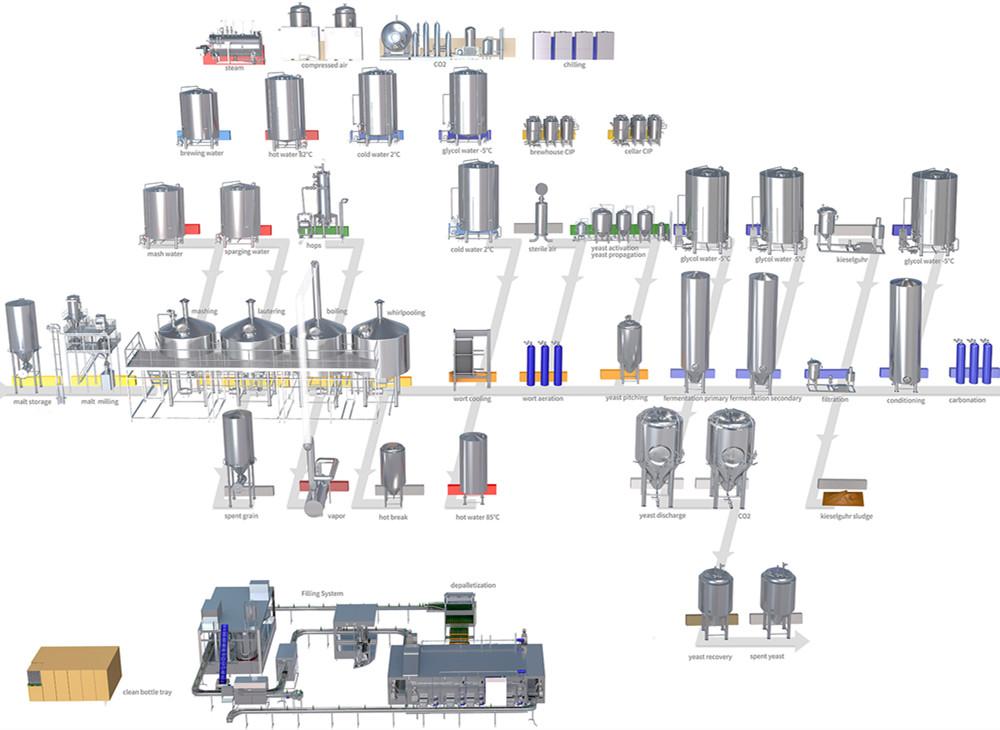

1200l 12HL 10BBL Micro Brewery Beer Brewing Equipment is often used in micro craft breweries or brewpubs. The system contains two vessels brewhouse, a mash/lauter tank and a boiling/whirlpool tank. The mashing process and the wort filtration process are completed by one tank, and the boiling and whirlpool processes are completed by one tank, saving equipment costs and floor space. This system usually brews one batch a day. If the second batch of brewing takes at least 14 hours, it can cope with a temporary increase in production and is not suitable for planned multi-batch brewing in one day. According to different fermentation cycles of brewed beer, 6pcs 2400L fermenters or 12pcs 1200L fermentors can usually be configured, and 4pcs 2400L fermenters and 4pcs 1200L fermenters can also be configured to meet the needs of various beer types. The system also needs to be equipped with a complete automatic or manual control system, malt milling system, CIP system, cooling system, steam heating system, air system, etc.

2.Our Advantage:

-With ISO TUV SGS, the product meets the GB/CE/PED/ASME standard

-Local service in EUROPE, AUSTRALIA ETC

-5 Years Warranty for tanks

-0 trade risk verified by more than 2600 breweries

-Build breweries in 106 countries

-20 Years Manufacture and Management Experience

3.Features

-Two/Three/Four vessels with hot water,first batch takes about 8 hours, and two batches of 14 hours are allowed;

-All certificated 304 stainless steel, easy to clean; Copper cladding for special environments such as bars;

-Steam heated, high thermal efficiency, gentle for wort; Electric or direct fire heating available;

-The wort cooled by tap water and -5 ºC ice water to cool in two stages, Single stage available;

-Mashing heating and fermentation cooling automatically controlled, and manual control switched at any time;

-Manual valve control, humanized operation, low equipment investment cost, high cost performance; PLC automatic control for upgrade;

4.Technique Details:

| Part 1: Malt Milling Unit | ||

| Malt Miller |

300-500kg/hr Rollers clearance adjustable for various malt particle Roller material: Hardening chrome steel, washable Roller speed differencial for higher malt efficiency |

1set |

| Part 2: 1200L Two Vessel/HLT Brewhouse | ||

| 12HL Mash/Lauter Tun |

Function: Grain mashing, wort Lautering, sparging High torque, low power consumption gear box Grain bed rake with positive inversion control Manually lifted spent grain dozer for spent grain out Side mounted enlarged spent grain manhole with glass with grain chute SUS304 wedge shape milling cut False Bottom/Filter plate with 0.7mm gap on top and 1.5mm bottom False bottom easy taken out from spent grain door Easy clean support at bottom for False bottom/Filter plate |

1set |

| 12HL Kettle/Whirlpool Tun |

Function: Wort boiling, hopping and whirlpooling Steam condenser with spray nozzle and valves Tangential whirlpool inlet with reducing port |

1set |

| 24HL Hot Water Tank |

Function: Hot water supplying Sanitary liquid level indicator with valves |

1set |

| Non-slip Work Platform |

Completely 304 stainless steel setup Non slip metal floor TH=3.0mm Integrated stairs or ladder Solid and ground hand rail |

1set |

| Sanitary Centrifugal Pump [LYSF] |

Wort Pump: 3M3/Hr, Sanitary SUS304, delivery 18m Motor brand: ABB with CE or WEG with UL/CSA/CE All motor with low noise, low vibration |

2sets |

| Sanitary Piping |

Complete 304SS with material certificate All pipe inside polished to sanitary grade All pipe machining comply to ISO, DIN, SMS or 3A standard |

1set |

| Valves and Fittings |

304SS butterfly valve Hygiene grade EPDM gasket Adjustable multi position handle |

1set |

| Water Mixing Station |

Function: Hot water and cold/city water blending and control Temperature and flow easy controled manually Adjustable valve in cold line and hot line |

|

| Wort Cooling Station |

Manual ball valve for cooling line Bimetallic thermometer for temperature display |

|

| 25L Glass Wort Grant |

Function: Buffer tank avoiding negative pressure in lauter tun Food grade glass side wall |

|

| 12M2 Heat Exchanger [304SS ] |

Effective Cooling Area: 4M2 Completely 304 Stainless steel Corrugated plates, TH=0.4mm All plates are numbered for easy assembling Heavy backplates with full sanitary stainless steel cover |

|

| Pipe Filter | Function: Protect heat exchanger from trub in wort | |

| Wort Aeration Station | Function: Inline O2 blending with wort | |

| 20L Yeast Feeder | Function: Inline yeast pitching for fermentable wort | |

| Part 3: Fermentation Unit | ||

|

10BBL/20BBL Fermenter |

Interior Shell: SUS304 full welded; TH=3mm Exterior Shell:SUS304 full welded; TH=2mm 100% TIG welding with pure argon gas shield Interior Finish: Sanitary 2B finish, Pickled and Passivated; (8K Mirror finish optional) Exterior Finish: Oil brushed finish (2B, 8K Mirror finish optional) Interior full polished to 0.2~0.4 μm without dead corner Insulation: TH=80mm with low thermal conductivity PU Cooling Jacket: Dimple plate on bottom and side wall, welded without over burning |

4sets |

|

10BBL/20BBL Bright Beer Tank |

Interior Shell: SUS304 full welded; TH=3mm Exterior Shell:SUS304 full welded; TH=2mm 100% TIG welding with pure argon gas shield Interior Finish: Sanitary 2B finish, Pickled and Passivated; (8K Mirror finish optional) Exterior Finish: Oil brushed finish (2B, 8K Mirror finish optional) Interior full polished to 0.2~0.4 μm without dead corner Insulation: TH=80mm with low thermal conductivity PU Cooling Jacket: Dimple plate on bottom and side wall, welded without over burning |

1set |

| Part 4: Glycol Cooling Unit | ||

| 2500L Glycol Water Tank |

Glycol Water inlet/outlet for chillers on side wall avoiding vortex and sediment Glycol Water inlet/outlet for cooling on side wall avoiding vortex and sediment |

1set |

| 5HP Glycol Water Chiller |

Type: Air cooled glycol water chiller Ambient Temp 35℃; Water outlet Temp -5℃ Refrigerant: Freon R407C envionmental friendly (Other Freon for special request) Programmed 5'' LCD control panel with water proof cover Automatic temperature controller Scroll Compressor [Key Part] by Copeland,Emmerson,Danfoss,Sanyo etc |

2sets |

| Glycol Water Pipeline |

Function: Glycol water circulation Glycol Water Pump 0.75kw 4M3/HR H=31m 304SS Solenoid valve DC24V for each tank PPR pipes and fittings Rubber foam Insulation for supply and return loops |

1unit |

| Part 5: Electric Control Unit | ||

| Brewhouse Control Cabinet |

Mash/Wort Pump on/off control Pump speed adjusted by VFD Rake/Agitator motor on/off control Rake/Agitator rotation speed adjusted by VFD Tanks heating control Auto/Manu switchable Level control for hot water tank with alarm |

1set |

| Fermentation Control Cabinet |

Glycol Water Pump on/off control Auto/Manu switchable Fermentation tanks cooling control Auto/Manu switchable Bright beer tanks cooling control Auto/Manu switchable Glycol water tank cooling control Auto/Manua switchable |

1set |

| Part 6: 100L Portable CIP Cart [Two Tanks] | ||

| 100L Portable CIP Cart [Two Tanks] |

100L Single Wall Caustic Tank 100L Single Wall Acid Tank Sanitary Centrifugal Pump Portable Trolley CIP Controlling Cabinet |

1set |

| Part 7: Auxiliary Equipment | ||

| 1-Station Keg Filler | ||

| 2-Station Keg Rinser | ||

| Bottling Machine | ||

| Canning Machine | ||

| Steam Boiler | ||

| Filter Machine | ||

5.Tiantai Company Profile

Tiantai Company, a well-recognized manufacturer of beer and beverage equipment industry based in Jinan city of China, provides complete lines and the turnkey service for breweries and beverage projects worldwide. Since 2001, Tiantai team has witnessed the rapid development of the industry with 23 years of experience. Founded in 2012 and followed by the boom of the craft beer market, Tiantai Company is committed to the research and the development of diverse brewing process, customized equipment, automatic control, and datalized management. Up to now, Tiantai Company has served over 2600 breweries in 106 countries with our equipment and solutions along with gaining good reputations.

Edited By Emily

Email Box: [email protected]

.jpg)

Get In Touch