1. Product Description

The 300L combined three-vessel brewhouse beer brewing system is often used in small craft breweries or craft brewing bars. The system includes mash lauter/whirlpool tun, kettle tun. The mashing process and the wort lautering process are completed in one vessel, under this vessel there is whirlpooling vessel. Saving equipment cost and floor space. This system usually brews one batches a day. If the second batch of brewing takes at least 14 hours, it can cope with a temporary increase in production and is not suitable for planned multi-batch brewing. According to different fermentation cycles of brewed beer, usually equip 4sets of 800L fermenters or 12 X 400L fermenters , and also can equip 4sets of 800L fermenters and 4sets of 400L fermenters to meet the needs of various beer types. The system also needs to be equipped with a complete automatic or manual control system, malt crushing system, CIP system, cooling system, steam heating system, air system, etc.

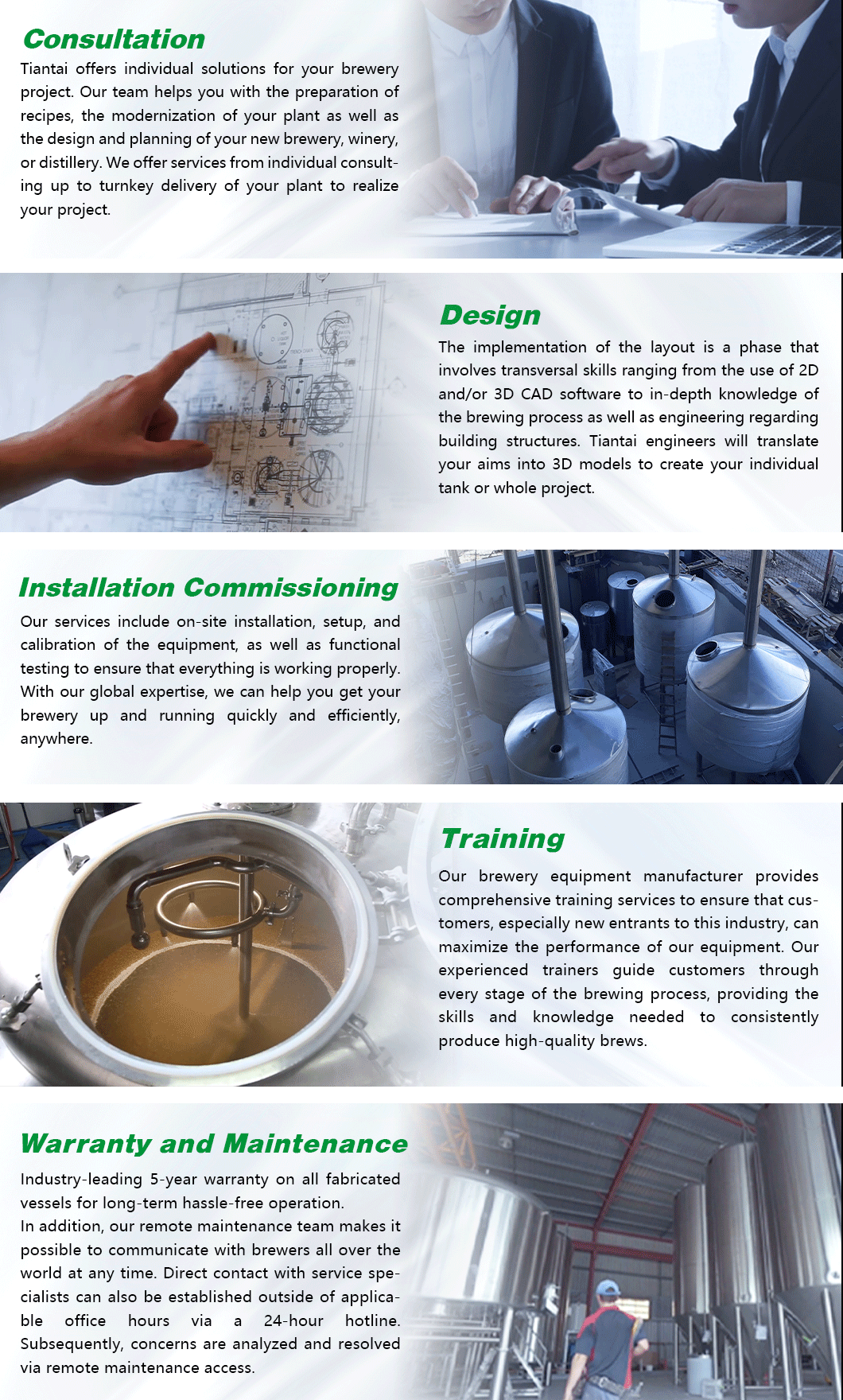

2. Product Advantages

♦Complete project delivery

♦5 Years Warranty for tanks

♦CE PED ISO9001 certificates, also satisfied with USA, Canada certifications requires

♦Automatic welding

♦Interiror full polished to 0.2~0.4 μm without dead corner

♦Customized diameter and brewery layout

♦Provided customer cases

3. Product Feature

♦ Combined three vessel brewhouse

♦ Electric heating with tubes freely,steam heating option

♦ Red copper exterior shell, food grade stainless steel 304 for interior shell, easy clean and very beautiful, shining.

♦Using two stages heat exchanger to cool the hot wort(First stage is city water, second stage is glycol water )

♦Automatic control for brewhouse heating, fermentation tanks temperature control Also can switch to manual control

♦ Manual butterfly valves, operation humanization, low costs, high costs effective.

4. Product Specification

| Part 1: Malt Milling Unit | ||

| Malt Miller [100-150kg/hr] | 1set | |

| Part 2: 300L Brewhouse | ||

| 300L Mash Lauter/Whirlpool Tun | 1set | |

| 300L Brew Kettle Tun | 1set | |

| Non-slip Work Plateform | 1set | |

| Sanitary Centrifugal Pump [LYSF] | 1set | |

| Sanitary Piping Valves and Fittings | 1set | |

| 25L Glass Wort Grant | 1set | |

| 4M2 Heat Exchanger [304SS NANHUA] | 1set | |

| Pipe Filter | 1set | |

| Wort Aeration Station | 1set | |

| 10L Yeast Feeder | 1set | |

|

Part 3: Fermentation Unit |

||

| 300L Fermentation Tank/Unitank | 4sets | |

| 300L Bright Beer Tank | 1set | |

|

Part 4: Glycol Cooling Unit |

||

| 600L Glycol Water Tank | 1set | |

| 5HP Glycol Water Chiller | 1set | |

| Glycol Water Pipeline | 1unit | |

|

Part 5: Electric Control Unit |

||

| Brewery Instrumental Control Cabinet | 1set | |

|

Part 6: Portable CIP Pump |

||

| Portable CIP Pump | 1set | |

|

Part 7: Spare Parts & Tools |

||

| 7.1 Spare Parts for brewhouse | 1set | |

| 7.2 Spare Parts for fermentation | 1set | |

| 7.3 Spare Parts for control | 1set | |

| 7.4 Spare Parts for CIP | 1set | |

| 7.5 Standard Installation Tools | 1set | |

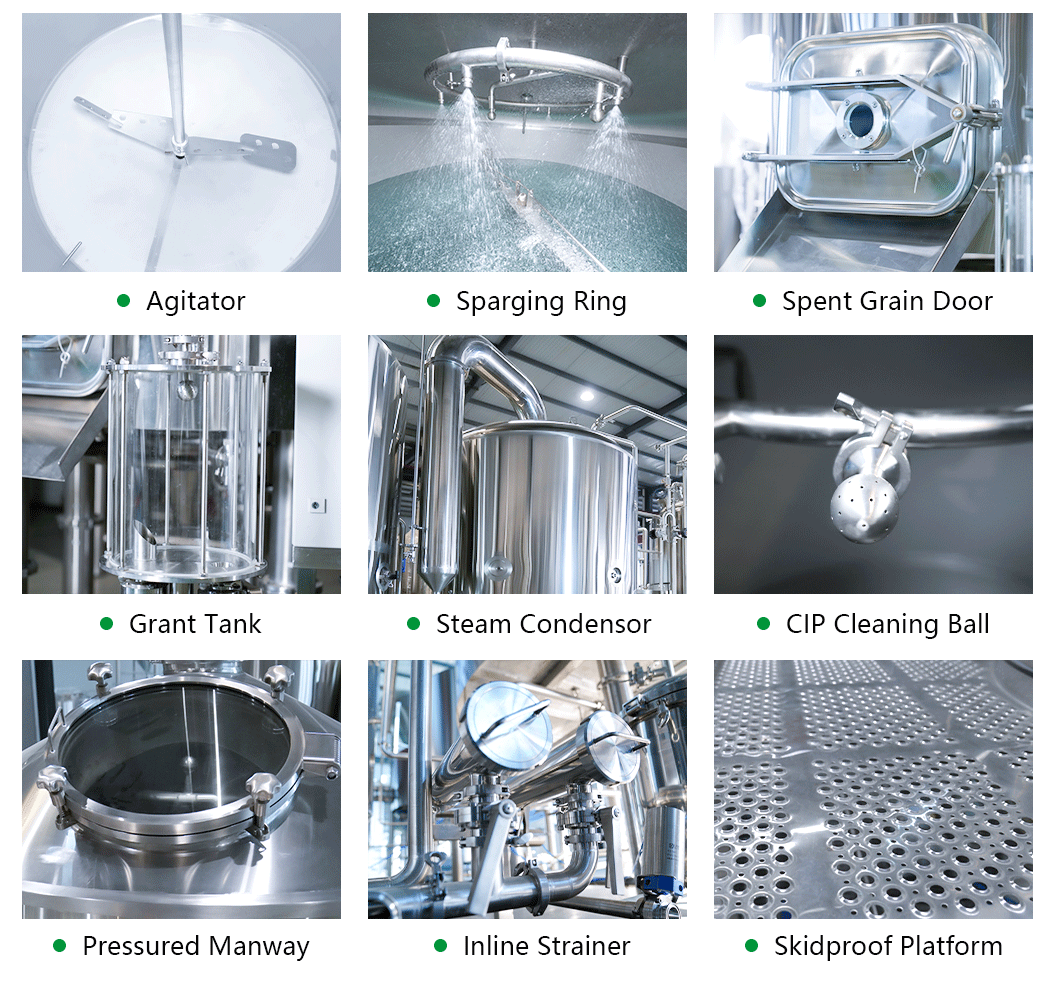

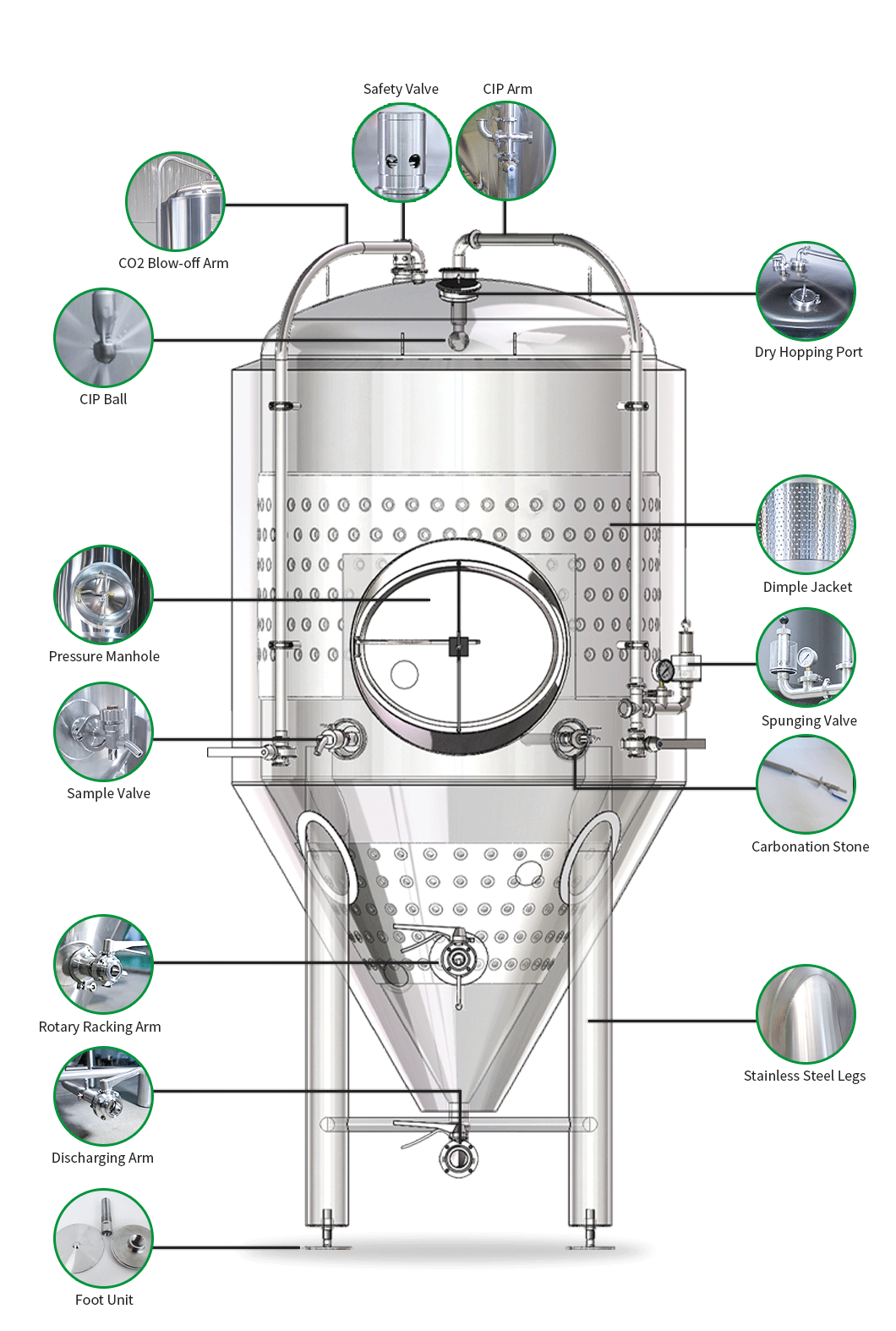

5. Details

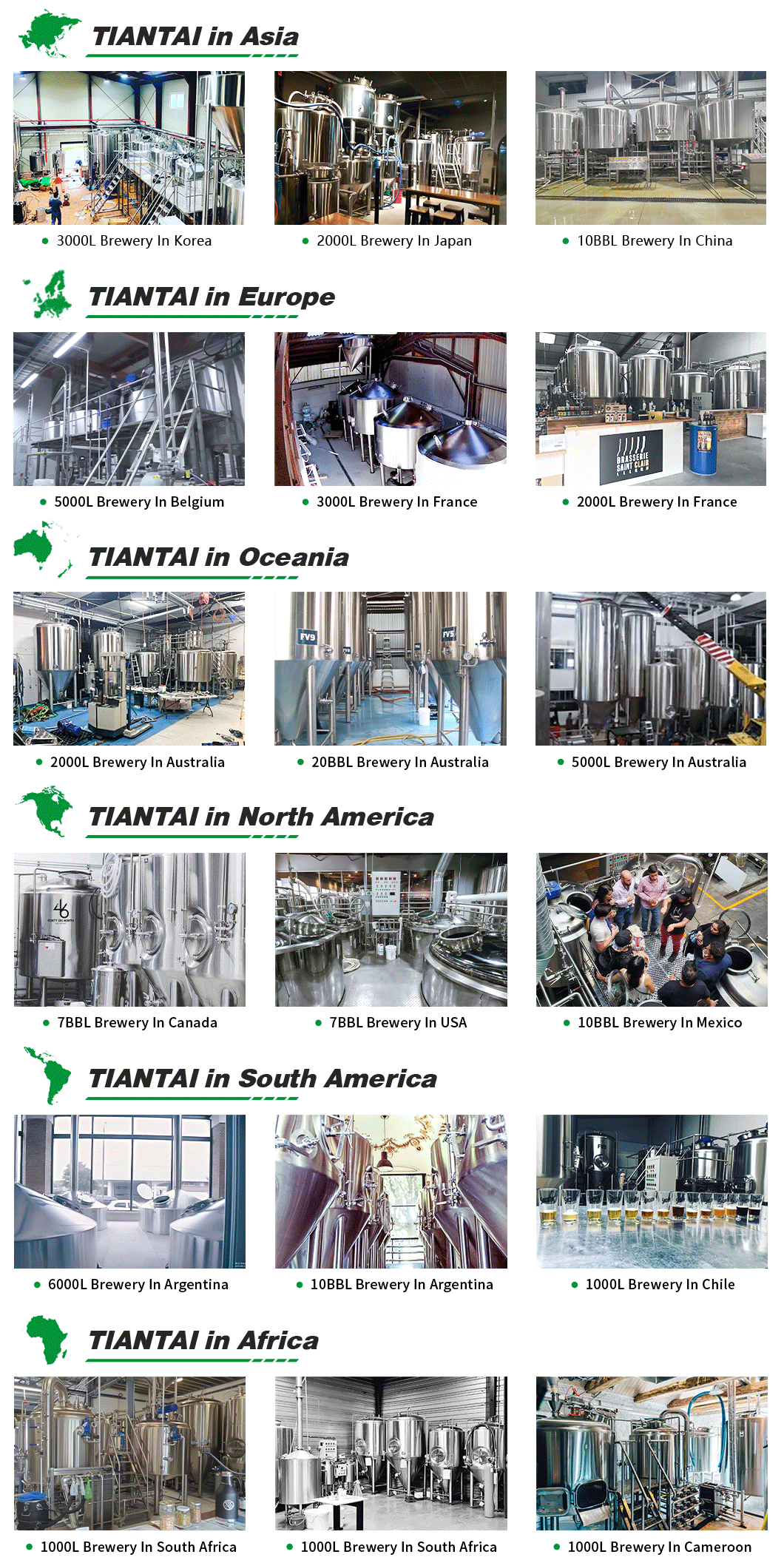

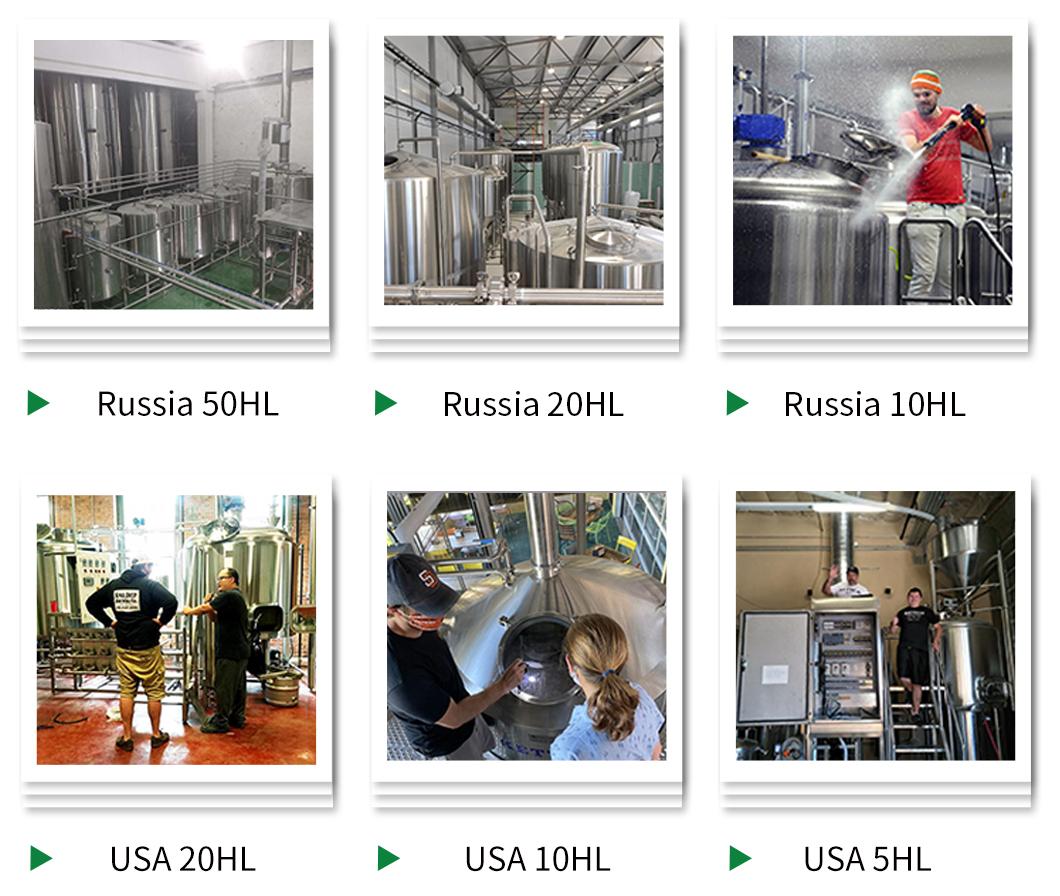

6.Cases worldwide

7. Certifcation

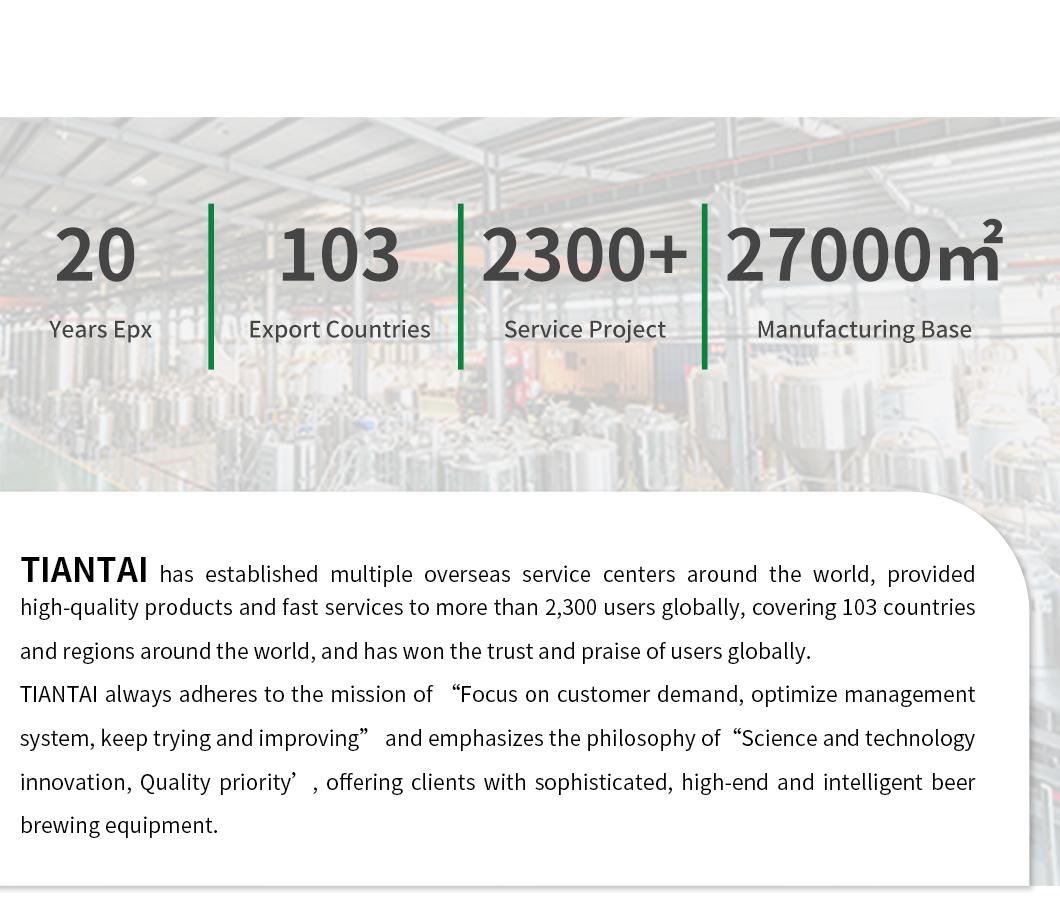

Tiantai Company, a well-recognized manufacturer of beer and beverage equipment industry based in Jinan city of China, provides complete lines and the turnkey service for breweries and beverage projects worldwide. Since 2001, Tiantai team has witnessed the rapid development of the industry with 23 years of experience. Founded in 2012 and followed by the boom of the craft beer market, Tiantai Company is committed to the research and the development of diverse brewing process, customized equipment, automatic control, and datalized management. Up to now, Tiantai Company has served over 2600 breweries in 106 countries with our equipment and solutions along with gaining good reputations.

Edited By Helen Lee

Sales manager

Email Box: [email protected]

Get In Touch