Fermentation vessels have always been an essential part of even the humblest home-based brewery. They have been almost infinitely varied over time; almost anything that can hold liquid can be a potential fermenter. That said, the technology used for fermentation vessels has progressed considerably during the past 50 years.

The modern beer fermentation tank has a cone bottom, the degree at 60°~90°, so this is better for yeast collection.

There is cooling jackets on the cylinder beer fermenter to cool the craft beer, usually there is 2-3 parts cooling jackets on the tank body, and one part cooling jackets on the cone bottom.

This is pressure tank, the working pressure is 2bar.

Some breweries will ask an atmosphere fermenter, without pressure, open top lid, 140~160°bottom cone. This kind of fermentation vessel will be used for traditional English beer fermenting.

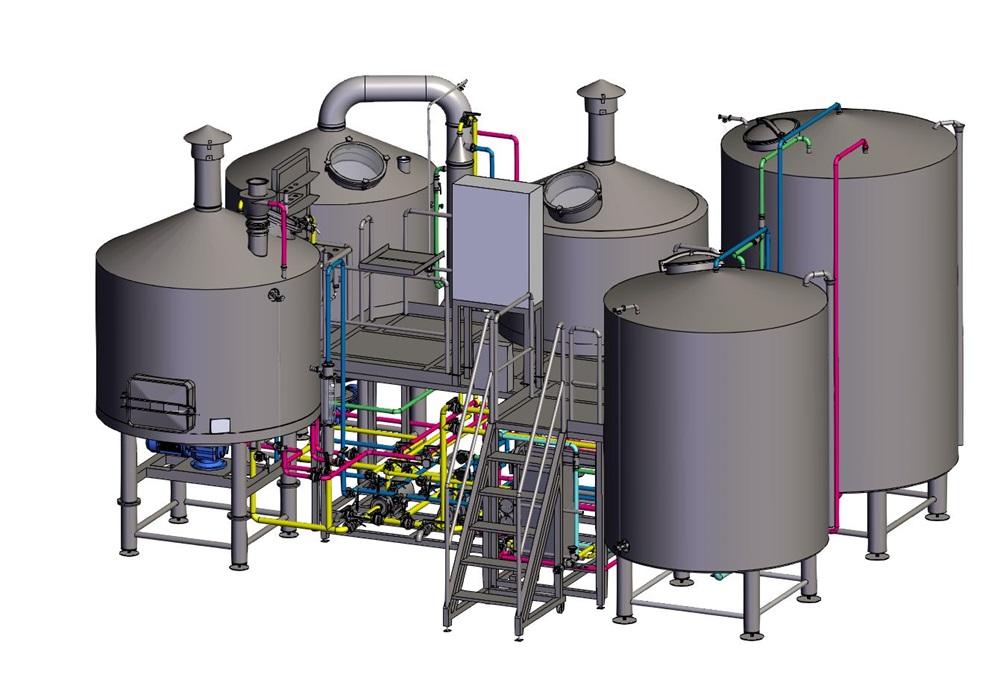

More and more breweries have customized beer fermentor or beer brewing system, brewhouse vessels to be satisfied with their special brewing technology. More ideas, more innovative beers. This is good! TIANTAI beer equipment company as a professional beer equipment & distillery manufacturer in China, we have own professional technology team and develop innovate department to provide special requires for every customer. If you are looking forward to build your own brewery or brewpub, or hotel, restaurant, please don’t hesitate to contact with us.

Edited By Daisy

[email protected]

.jpg)

Get In Touch