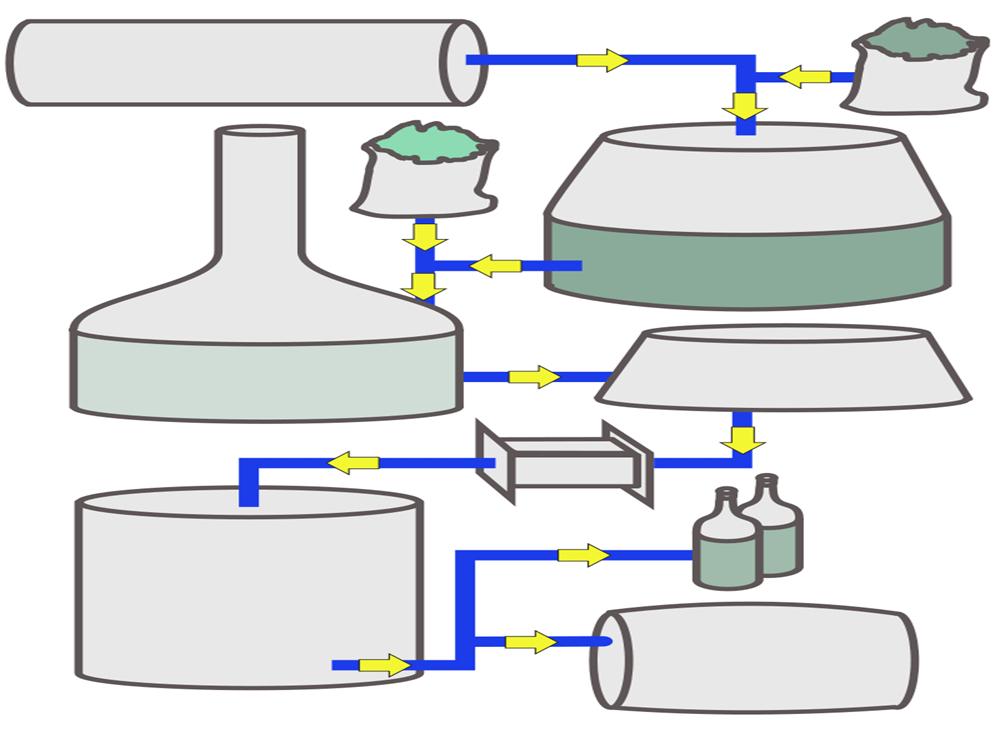

Malting is the process where barley grain is made ready for brewing in miller system. Malting is broken down into three steps to help to release the starches in the barley. First, during steeping, the grain is added to a vat with water and allowed to soak for approximately 40 hours. During germination, the grain is spread out on the floor of the germination room for around 5 days. The final part of malting is kilning when the malt goes through a very high temperature drying in a kiln in a brew house also called brewing house; with gradual temperature increase over several hours. When kilning is complete, the grains are now termed malt, and they will be milled or crushed to break apart the kernels and expose the cotyledon, which contains the majority of the carbohydrates and sugars; this makes it easier to extract the sugars during mashing.

Mashing converts the starches released during the malting stage into sugars that can be fermented. The milled grain is mixed with hot water in a large vessel known as a mash tun. In this vessel, the grain and water are mixed to create a cereal mash. During the mash, naturally occurring enzymes present in the malt convert the starches (long-chain carbohydrates) in the grain into smaller molecules or simple sugars (mono-, di-, and tri-saccharides). This "conversion" is called saccharification which occurs between the temperatures 60–70 °C (140–158 °F). The result of the mashing process is a sugar-rich liquid or "wort", which is then strained through the bottom of the mash tun in a process known as lautering. Before lautering, the mash temperature may be raised to about 75–78 °C (167–172 °F) (known as a mashout) to free up more starch and reduce mash viscosity. Additional water may be sprinkled on the grains to extract additional sugars (a process known as sparging).

The wort is moved into a large tank known as a "copper" or kettle tun in brewing house where it is boiled with hops and sometimes other ingredients such as herbs or sugars. This stage is where many chemical reactions take place, and where important decisions about the flavor, color, and aroma of the beer are made. The boiling process serves to terminate enzymatic processes, precipitate proteins, isomerize hop resins, and concentrate and sterilize the wort. Hops add flavor, aroma and bitterness to the beer. At the end of the boil, the hopped wort settles to clarify in a vessel called a "whirlpool", where the more solid particles in the wort are separated.

After the whirlpool process in brewhouse, the wort is drawn away from the compacted hop trub and rapidly cooled via a heat exchanger to a temperature where yeast can be added. A variety of heat exchanger designs are used in breweries, with the most common a plate style. Water or glycol run in channels in the opposite direction of the wort, causing a rapid drop in temperature. It is very important to quickly cool the wort to a level where yeast can be added safely as yeast is unable to grow in very high temperatures, and will start to die in temperatures above 60 °C (140 °F). After the wort goes through the heat exchanger, the cooled wort goes into a fermentation tank also called fermenter. A type of yeast is selected and added, or "pitched", to the fermentation tank. When the yeast is added to the wort, the fermenting process begins, where the sugars turn into alcohol, carbon dioxide, and other components. When the fermentation is complete the brewer may rack the beer into a new tank, called a conditioning tank. Conditioning of the beer is the process in which the beer ages, the flavor becomes smoother, and unwanted flavors dissipate. After conditioning for a week to several months, the craft beer may be filtered and force carbonated for bottling, or fined in the cask or beer keg.

Learn more how Tiantai beer equipment company to not only produce the best quality brewery equipment for flavor-rich beers, but also help them to optimize the configuration, maximize process uptime and reduce beer loss when they brewing, PLEASE DON’T HESITATE TO CONTACT WITH US!

Hubert

Email: [email protected]

.jpg)

Get In Touch