Material and Construction:

Vinegar ferment tanks are typically constructed from food-grade 304 stainless steel that are resistant to corrosion and chemical reactions. Stainless steel is a popular choice due to its durability, hygiene properties, and ease of cleaning. The tank's construction should ensure airtightness to prevent oxygen leakage, as oxygen is vital for the growth and activity of acetic acid bacteria.

Capacity:

Vinegar ferment tanks come in various sizes to accommodate different production volumes. The capacity of the tank depends on the scale of the vinegar production operation. Small-scale artisanal producers may opt for tanks with capacities ranging from a few hundred liters to a few thousand liters, while larger commercial facilities might require tanks with capacities in the tens of thousands of liters.

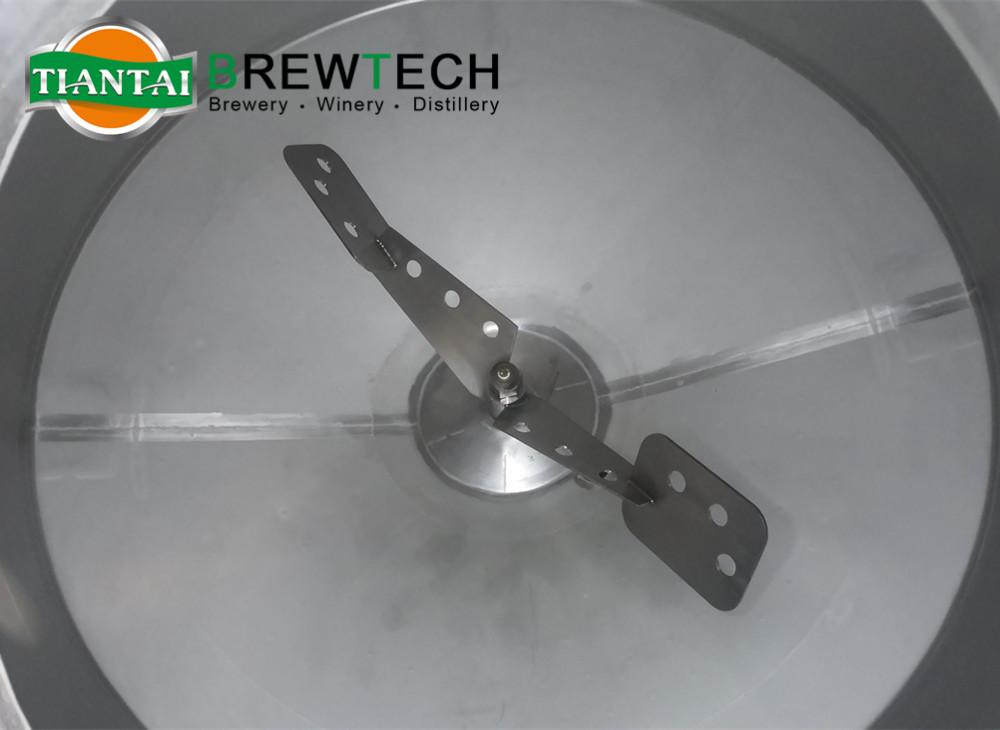

Aeration System:

A crucial aspect of vinegar fermentation is the availability of oxygen to support the growth and metabolism of acetic acid bacteria. Vinegar ferment tanks are equipped with aeration systems that supply a controlled flow of oxygen to the fermenting liquid. This can be achieved through diffusers, spargers, or other mechanisms that ensure efficient oxygen dispersion throughout the tank.

Temperature Control:

Maintaining optimal fermentation temperatures is vital for the activity of acetic acid bacteria. Vinegar ferment tanks incorporate PT100 temperature sensor to regulate and stabilize the internal temperature. This can be achieved through heating elements, cooling jackets, or external temperature control devices, depending on the specific tank design.

pH Control:

Acetic acid bacteria thrive in specific pH ranges, typically between 5.0 and 6.0. Vinegar ferment tanks feature pH control mechanisms to monitor and adjust the acidity level throughout the fermentation process. pH sensors and automated dosing systems may be employed to maintain the desired pH range for optimal bacterial growth and acid production.

Sedimentation and Separation:

During vinegar fermentation, a slimy sediment known as the "mother" is formed. Vinegar ferment tanks should incorporate features that aid in the separation of the mother from the finished vinegar. This may include sedimentation zones, settling chambers, or filtration systems to ensure the production of clear and high-quality vinegar.

Monitoring and Control Systems:

Advanced vinegar ferment tanks may include monitoring and control systems that offer real-time data on critical parameters such as temperature, pH, oxygen levels, and fermentation progress. These systems enable operators to make informed adjustments and optimize the fermentation conditions, leading to improved efficiency and consistent vinegar quality.

Vinegar ferment tanks with their specific specifications are essential components in the vinegar production process. By providing the ideal environment for acetic acid bacteria, these tanks ensure efficient fermentation and the production of high-quality vinegar.

Tiantai company offers a comprehensive range of brewing equipment and fermenting equipment for beer, kombucha, cider, cold brew coffee, seltzer, vinegar and more.

If you are interested in receiving detailed specifications and pricing information about Tiantai's brewery equipment, please reach out to us.

Contact Information:

Email: [email protected]

Contact Person: Emily Gong

.jpg)

Get In Touch