1. Raw Water Filtration

Raw water filtration first needs to undergo activated carbon filtration, followed by microfiltration. Activated carbon filtration is mainly used for organic impurities in water, colloidal micro-particles, and the removal of color and odor in clear water. Microfiltration machines, as precision filtration and sterilization equipment, can filter particles and bacteria above 0.01μm in liquids and gases. Its features include high capture efficiency, large filtration area, long service life, high filtration accuracy, low resistance, strong mechanical strength, no peeling phenomenon, strong acid-base resistance, and easy use.

_副本.jpg)

2. Mixing Tank Configuration

The mixing tank, including the cylinder body, cylinder cover, agitator, inlet port, and outlet valve, is made of SUS304 or 316 stainless steel, according to the technical conditions of GB741-80. The inner surface is mirror-polished to Ra≤0.28μm, and the outer surface is polished, mirrored, sandblasted, or cold-rolled original matte. The tank body has an agitator for stirring. The openings include a liquid level gauge (static pressure type, capacitance type, non-contact type, ultrasonic type, glass tube type), air breathing port, thermometer (digital or dial type), CIP cleaning port, sight glass, explosion-proof sight light (integrated with sight glass), SIP sterilization port, in and out liquid ports, and sanitary manholes.

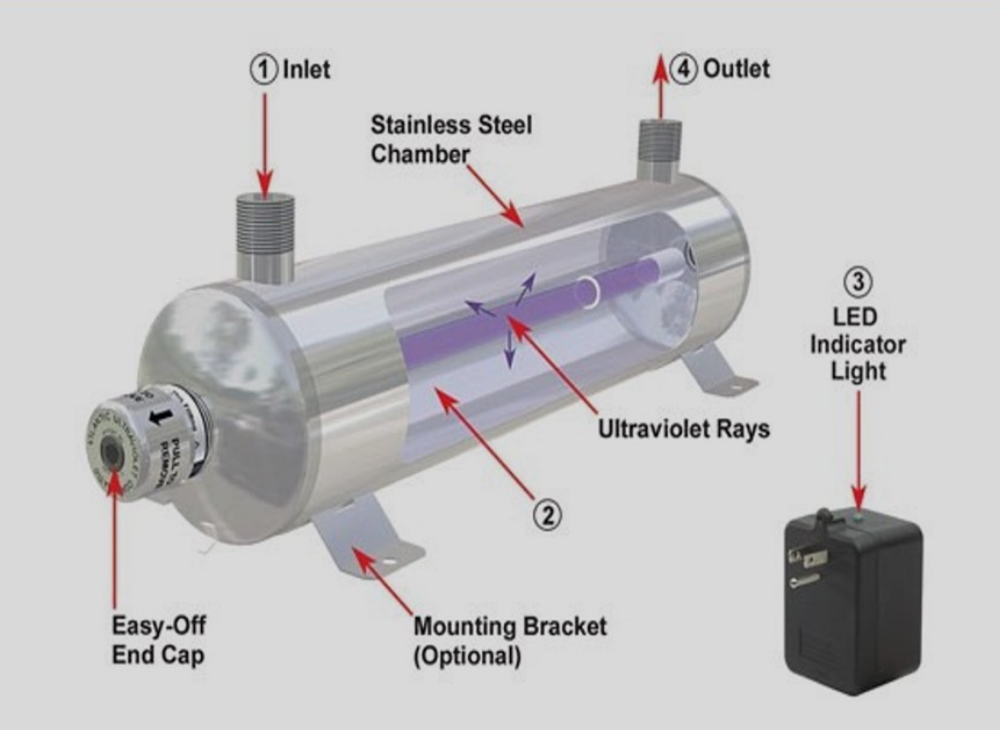

3. Sterilization

sterilizer utilizes the strong oxidizing properties of ozone to achieve sterilization. Ozone is a potent oxidant, with a sterilization effect 15 to 30 times higher than chlorine. It acts in 5 to 10 minutes at a certain concentration and can achieve sterilization against various types of bacteria.

4. Filling

Aseptic filling machines are widely used in the aseptic packaging of fluid foods such as fruit juice, pulp, and jam. At room temperature, the product can be preserved for over a year, eliminating the cost and risk of low-temperature refrigerated transportation. The aseptic filling machine is directly connected to the sterilizer and fills the product directly after sterilization.

_副本.jpg)

5. Packaging Inspection

Packaging inspection involves checking the product packaging and packaging symbols according to contracts, standards, and other relevant regulations. It begins by verifying whether the product packaging symbols (labels, numbers, etc.) on the outer packaging match the trade contract. The main inspection focuses on whether the outer packaging is intact, whether packaging materials, methods, and cushioning comply with contract requirements. For damaged outer packaging, additional residual inspection is carried out to determine the party responsible for the damage and its extent. The inspection also checks whether damage to the product is caused by poor packaging. In addition to meeting the trade contract and standard requirements, packaging inspection also evaluates whether the inner and outer packaging of the product is firm, complete, dry, clean, suitable for long-distance transportation, and meets customary requirements for protecting product quality and quantity. Inspection of packaging for imported and exported goods is generally carried out through sampling or on-site inspection, or it may be combined with scale weighing during inspection.

6. Finished Product

Finished products must have intact packaging without squeezing or damage, and the date, text, images, and barcodes on the outer packaging must be clear and visible. Only finished products that pass inspection can be shipped.

Hubert

[email protected]

.jpg)

Get In Touch