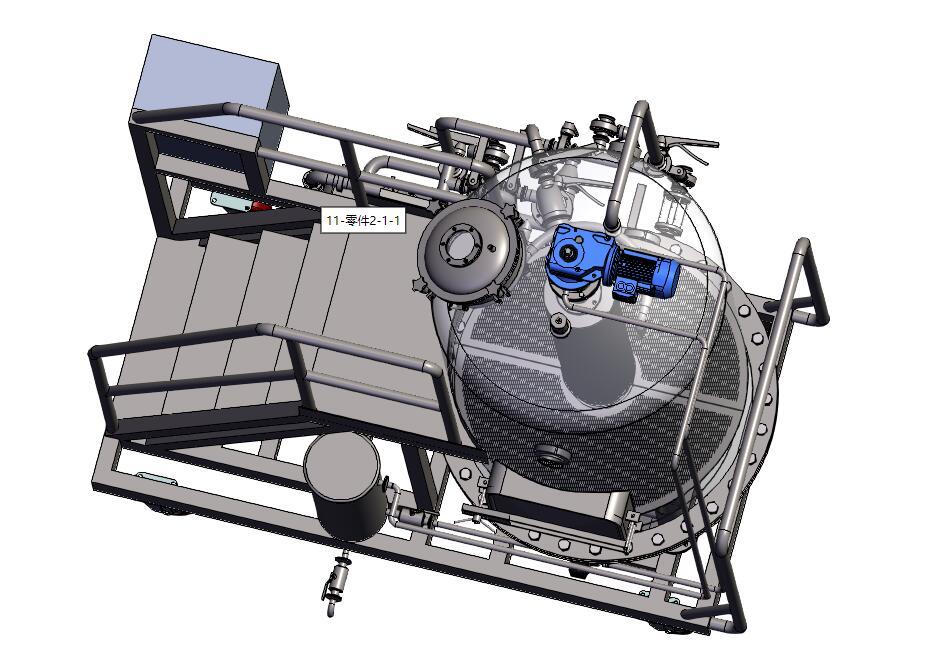

Here is a drawing of 500L Hop Extraction Tank we designed for other breweries before.

We designed it with mixer motor at the top,and the motor will rotate the filter screen inside the tank,with this design, It will achieve mixing beer and hops better.

The mixer motor will keep turning and getting hot, So there is one cold water tank for cool the motor.

The diaphragm pump will be mounted on the skid.

The 500L hop extraction tank will be too high for operate, we designed platform for you operate on it, everything will be mounted on a skid ,and could be moved.

Here’s a general guide to help you with the design process:

1. Purpose and Process

Purpose: Extracting hop oils, alpha acids, and aromas for dry hopping, whirlpool hopping, or specialized hop extracts.

Method: Typically, hop extraction tanks use recirculation, agitation, or CO2-purging to enhance extraction.

2. Material and Construction

Material: Stainless Steel 304/316 (food-grade, corrosion-resistant).

Wall Thickness: 3-5 mm for durability and pressure resistance.

Finish: Mirror-polished interior for easy cleaning and reduced hop adherence.

3. Tank Design

Capacity: 500L with 10-20% headspace to prevent overflow during agitation.

Shape: Cylindrical with a conical bottom (30-45° angle) for easy hop removal.

Top: Dome-shaped with a manway for adding hops and cleaning access.

4. Agitation and Extraction Efficiency

Recirculation Pump: Integrate a CIP (clean-in-place) pump loop to continuously circulate wort through the hops.

Agitator or Rake: Optional mechanical agitator to keep hops suspended.

Sparging Arm: Introduce CO2 or N2 at the bottom to create turbulence and extract oils effectively.

5. Flow and Filtration

Inlet/Outlet:

Inlet: Tangential or side inlet for even hop saturation.

Outlet: Bottom center with a mesh filter or hop sock to separate solids from liquid.

Valves: Tri-clamp butterfly valves for ease of operation and disassembly.

Sight Glass: To monitor flow and extraction progress.

6. Pressure and Temperature Control

Pressure Rating: Up to 2 bar to handle pressure buildup during extraction.

Cooling Jacket: Optional glycol jacket to control temperature and prevent unwanted isomerization.

7. Cleaning and Maintenance

CIP System: Spray ball or rotary spray head for effective internal cleaning.

Drainage: Full-drain design with minimal dead space to ensure no hop residues are left behind.

8. Automation and Monitoring (Optional)

Control Panel: Temperature, pressure, and recirculation flow monitoring.

Sensors: Pressure and temperature probes to automate the extraction process.

9. Key Considerations for Space

Ensure the tank fits through your freight elevator. Modular designs with detachable legs or top sections might help with space constraints.

Would you like more detail on materials, suppliers, or specific component dimensions? Feel free to contact Tiantai Brewtech to get your solution.

Contact email:[email protected]

Helen Lee

Sales manager

.jpg)

.jpg)

Get In Touch