1.Production Description

The packaging options include glass bottles, cans, kegs, and PET bottles. These are distributed to various outlets, such as supermarkets, restaurants, bars, and pubs.

It is recommended that breweries be located in industrial parks and simplify logistics to guarantee the freshness of the beer.

| Annual total | 50 million liters |

| Annual maximal | 70 million liters |

| Brewhouse output per batch | 15000 liters |

| Cellar capacity | >3000000 liters |

| Annual filling capacity | 60 million liters |

2.Product Advantages

--With ISO TUV SGS, meets GB/CE/PED/ASME standard

--Local service in EUROPE, AUSTRALIA, etc

--5 Years Warranty for tanks

--0 trade risk verified by more than 2600 breweries

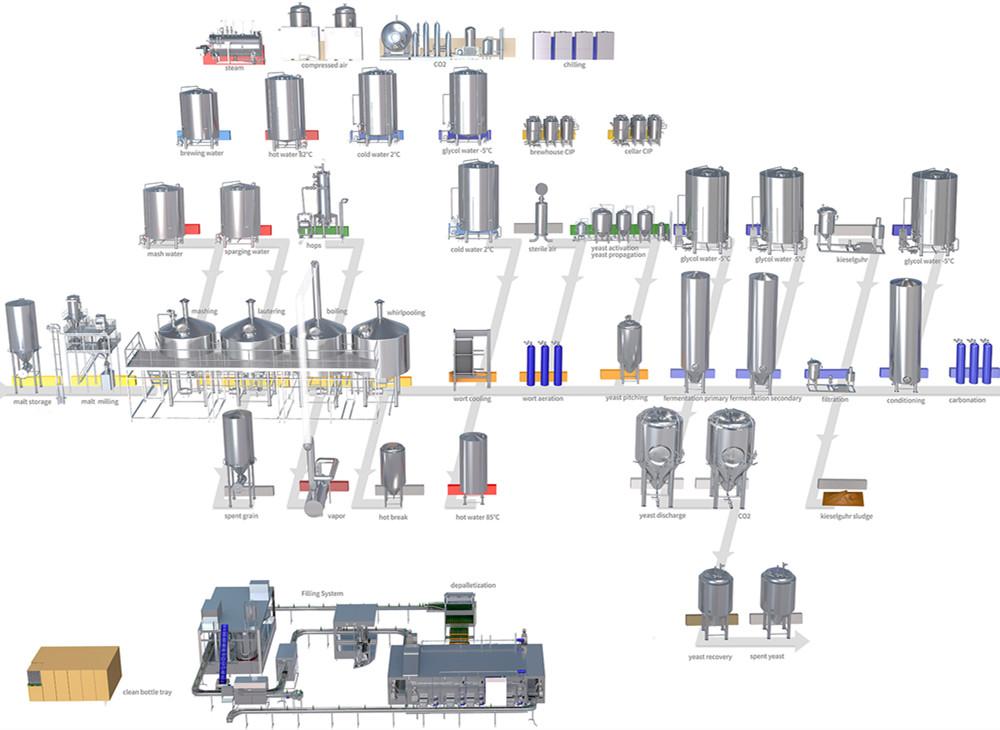

3. Main components:

Malt Storage System

Malt Milling System

Brewhouse System

Fermentation System

Filtration System

Maturation and Conditioning

Pasteurization System

Control System

CIP System

Hot Water Supply

Cold Water Supply

Brewing Water Supply

Refrigeration System

Water Deaeration Systems

Reverse Osmosis System

Steam Supply System

Compressed Air Supply System

CO2 Supply System

Electricity Supply System

Filling System (bottle/can/keg)

Commercial breweries usually needs to be a turnkey project with complete sets. Its energy consumption shall be accurately calculated to provide stable data supports for the cost control of operation. The beer quality from commercial breweries shall be consistant all the time to keep the taste. Therefore, a well-controlled recipe would be required to ensure the uniform quality for each brewing batch. Commercial brewery systems are usually integrated with modules and full automation to get a high brewing efficiency. Sanitary pipelines with reasonable design and scientific cleaning method are also key to ensuring an unpolluted brewing process.

4.Quality Control

Product quality control should be carried out in the whole process, which not only includes quality control throughout the manufacturing process, but also requires quality control in the previous communication process and technical design process. The design of craft brewery projects are subject to the changes of personalized requirements, multiple configurations, and various floor plans. Therefore, it is key to accurately meet user needs.

We decompose all the parameter of each item into standardization, save them as a standard database, and convert them into standard text descriptions and technical descriptions. In this way, it helps to realize the unambiguous communications from users, our sales staff, to our technical team. Every user will be served by the same sales staff and the technician throughout the whole process from the pre-sales consultation to the order delivery, which greatly helps to avoid any information loss when handing over the works among different teams in different working process.

Technical design, as the hub of project execution, shall be strictly followed by the manufacturing. Of course, the manufacturing process must be carried out along with the all-round and full-process quality control, from the selection of raw materials, the inspection of raw materials when arrival, to the product processing. Our guarantees of reliable quality cover aspects of stable and reliable raw material supply, scientific and reasonable production process design, strict processing standards, professional staff skills training, advanced processing facilities and comprehensive quality inspection system.

5.Tiantai Company Profile

Contact Information:

Email: [email protected]

Contact Person: Emily Gong

Get In Touch