High-Temperature Fermentation: A Key Brewing Technique

In the world of beer brewing, fermentation processes are typically categorized into two main types based on the temperatures used: low-temperature fermentation and high-temperature fermentation. While the former is well-established for producing certain beer styles, high-temperature fermentation has gained popularity for its efficiency and versatility, particularly in large-scale brewing operations. In this article, we will explore the nuances of high-temperature fermentation, its methods, advantages, and challenges, while also considering its implications for modern brewing.The Concept of High-Temperature Fermentation

High-temperature fermentation involves carrying out the brewing process at elevated temperatures, generally ranging from 14°C to 17°C, as opposed to the cooler temperatures used in traditional lager brewing. This method is widely adopted in breweries looking to optimize equipment utilization, shorten production cycles, and reduce costs, all while maintaining the quality of the final product.Typically, the high-temperature fermentation process, including maturation and storage, can be completed within 17 to 20 days, significantly shorter than traditional methods. Some advanced breweries have streamlined the process further, achieving fermentation and maturation within 12 to 15 days. This efficient method has become a cornerstone for modern breweries that prioritize operational speed without compromising beer quality.

The One-Tank Method High-temperature fermentation is often implemented using the one-tank method, where the entire fermentation process, from primary fermentation to maturation, is carried out in a single conical fermentation tank. This streamlined approach eliminates the need for transferring beer between tanks, reducing the risk of contamination and simplifying the overall brewing process.

.jpg)

Detailed Process of High-Temperature Fermentation

The high-temperature fermentation process involves several meticulously controlled steps to ensure consistent quality:1. Wort Cooling and Aeration:

After boiling, the wort is transferred to a whirlpool to remove hot break material and hop residues. It is then cooled to 9.5°C to 10°C using a plate heat exchanger. To further refine the wort, flotation techniques are used to remove cold break material, ensuring a clear liquid. During this stage, sterile air is introduced to achieve a dissolved oxygen content of 7–8 mg/L, which is crucial for healthy yeast activity.

2. Yeast Addition and Initial Fermentation:

The wort’s original gravity is set to 12°P, and 0.6%–0.8% of mud-like yeast is added. The wort is maintained at 10°C–11°C for approximately 36 hours to allow for yeast propagation.

3. Temperature Increase for Primary Fermentation:

After the initial propagation phase, the temperature is gradually increased to 12°C to initiate the main fermentation. During this stage, yeast converts sugars into alcohol and carbon dioxide, creating the distinct flavors of beer.

4. Controlled Fermentation:

After about two days, when the apparent extract concentration drops to 6°P, the tank pressure is increased to 0.08–0.1 MPa. The temperature is then allowed to naturally rise to 16°C, facilitating the reduction of diacetyl, a compound that can impart unwanted buttery flavors if not properly managed.

5. Completion of Primary Fermentation:

By the fifth day after tank filling, the apparent sugar content typically reaches its lowest point (2.2–2.5°P). By the seventh to ninth day, diacetyl levels drop below 0.1 mg/L, marking the readiness of the beer for maturation.

6. Cooling and Maturation:

The beer is slowly cooled to 0°C over the next four to five days, allowing for maturation and CO₂ saturation. During this stage, unwanted flavors mellow, and the beer develops a balanced taste. Yeast is collected and removed on the second day of cooling, with additional yeast and cold break removal before transferring the green beer.

.jpg)

Advantages of High-Temperature Fermentation

High-temperature fermentation, especially using the one-tank method, offers numerous advantages that make it appealing to modern breweries:1. Efficiency:

The process is faster than traditional methods, significantly reducing the time required for fermentation and maturation.

2. Simplified Operations:

The one-tank method eliminates the need for transferring beer between tanks, reducing labor and equipment costs.

3. Improved Equipment Utilization:

By shortening the fermentation cycle, breweries can maximize the use of their fermentation tanks, leading to higher production capacity.

4. Reduced Risk of Contamination:

Fewer transfers mean fewer opportunities for the beer to come into contact with contaminants.

5. Lower Production Costs:

With shorter cycles and reduced cleaning requirements, operational costs are significantly lowered.

6. Automated Controls:

Temperature, pressure, and liquid levels can be easily monitored and controlled using automated systems, ensuring consistency.

7. Ease of Yeast Recovery:

The conical design of the fermentation tanks allows for efficient yeast collection and reuse, further reducing costs.

Challenges of High-Temperature Fermentation

Despite its numerous benefits, high-temperature fermentation is not without its challenges:1. Flavor Profile:

The strong convection currents within the fermentation tank can prevent complete separation of impurities, resulting in a beer that may have a harsher taste compared to beer produced using two-tank methods.

2. Bitterness Characteristics:

Beers brewed using the one-tank method often exhibit a sharper and more pronounced hop bitterness, which may not be desirable for all beer styles.

3. Tank Utilization Limits:

To accommodate fermentation expansion, a portion of the tank's capacity must remain unused, reducing its overall efficiency.

Tiantai’s Role in Modern Brewing

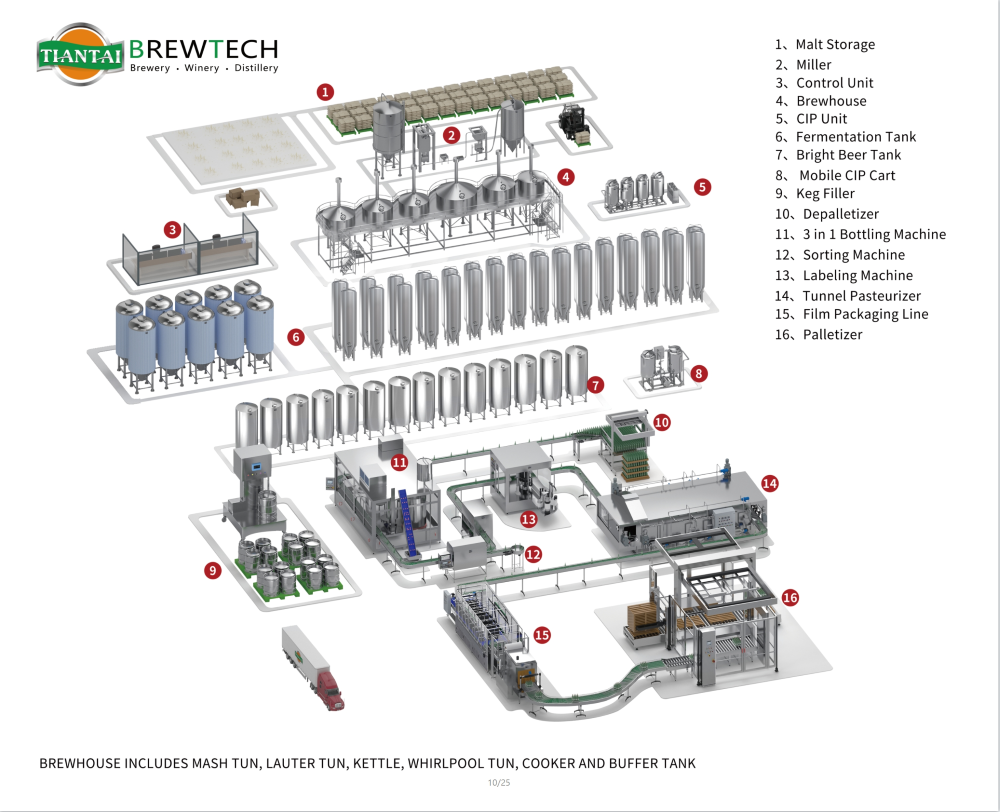

At Tiantai Beer Equipment Company, we specialize in providing customized brewing solutions tailored to the unique needs of breweries. Our expertise extends beyond manufacturing equipment—we delve deeply into the brewing process to better understand our clients’ requirements. Whether you need a bespoke brewhouse system or advanced conical fermentation tanks, Tiantai is dedicated to delivering equipment that enhances both efficiency and quality.Share Your Brewing Journey

What fermentation techniques does your brewery use? Do you prefer traditional low-temperature methods, or have you adopted high-temperature fermentation for its efficiency? We’d love to hear your experiences and insights.At Tiantai, we’re more than just a supplier—we’re your partner in brewing success. Contact us today to discuss how we can support your brewing ambitions with reliable, state-of-the-art equipment tailored to your specific needs.

.jpg)

This exploration of high-temperature fermentation highlights its importance as a modern brewing method. With its numerous advantages, it has become a go-to choice for breweries striving for efficiency and quality. At the same time, Tiantai Beer Equipment is here to support brewers every step of the way, ensuring they have the tools and expertise needed to excel.

Edited By Daisy

[email protected]

.jpg)

Get In Touch