Conical Fermenters and the Low-Temperature Fermentation Process

In modern breweries, conical fermenters have become the standard equipment for primary fermentation and maturation due to their operational efficiency and labor-saving design. These fermenters not only streamline the brewing process but also enable breweries to maximize equipment utilization without compromising beer quality. The key to achieving this efficiency lies in fermenting and maturing the beer in the shortest possible time. Among the various fermentation methods, beer fermentation can be categorized into low-temperature fermentation and high-temperature fermentation, depending on temperature control.Low-temperature fermentation is particularly common in China, where traditional brewing methods and yeast strains are often used in conjunction with conical fermenters. So, what exactly is the low-temperature fermentation process?

The Low-Temperature Fermentation Process

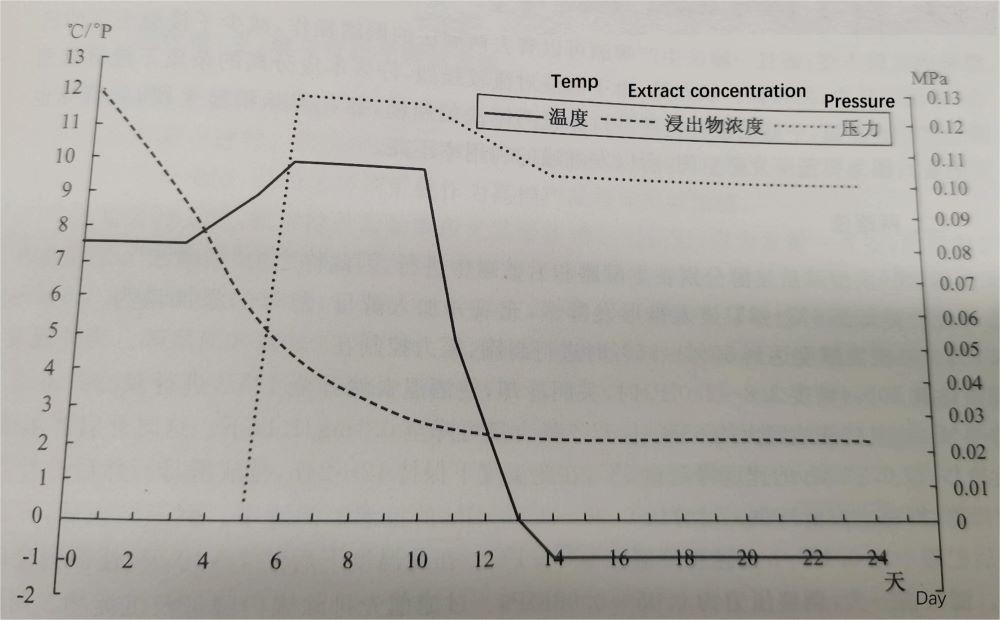

Low-temperature fermentation begins with hot wort. After boiling, the wort undergoes whirlpool sedimentation to remove hot break and spent hops. It is then cooled through a plate heat exchanger to reach an inoculation temperature of 6°C to 8°C. At this stage, sterile air is introduced to achieve a dissolved oxygen concentration of 7–8 mg/L. Yeast is inoculated at a rate of 0.5% to 1.0% of the wort volume. Once inoculated, the wort is pumped into the fermenter for fermentation.The fermenter is typically filled to 80–90% of its capacity to allow for optimal fermentation dynamics. During the initial phase of fermentation, the temperature is maintained at the inoculation temperature (6°C–8°C) for three days. Subsequently, the temperature is allowed to naturally rise to 10°C. This temperature is then maintained for the duration of the primary fermentation process.

When the apparent degree of fermentation (ADF) reaches 55%, pressure inside the fermenter is increased to 0.07–0.1 MPa. This pressurization accelerates the reduction of diacetyl, a compound that can impart undesirable buttery flavors if left unchecked. Additionally, the increased pressure minimizes the production of higher alcohols and esters, which could negatively impact the flavor profile of the beer.

After approximately 3–4 days, when the diacetyl concentration drops below 0.1 mg/L, the temperature of the beer is gradually lowered at a rate of 0.3°C per hour until it reaches 5°C. At this point, two pathways are available:

1. Stabilization at 5°C

The beer is held at 5°C for 24 hours to allow for yeast flocculation and partial separation. Yeast is then either removed or harvested. Following this, the temperature is further reduced at a slower rate of 0.1°C per hour until it reaches 0°C to -1°C.

2. Continuous Cooling

Alternatively, the temperature is not held at 5°C but continues to decrease at 0.1°C per hour until it reaches 0°C to -1°C.

Secondary Yeast Removal and Maturation

Once the beer reaches the target low temperature, yeast and other sediments are allowed to settle, and a second round of yeast separation is performed after 24 hours. The beer is then stored at 0°C to -1°C for an additional 10–15 days, allowing for maturation.During this storage period, undesirable compounds such as sulfur-based off-flavors and residual diacetyl are further reduced. The extended contact time at low temperatures enhances the beer's overall clarity, stability, and flavor profile.

Filtration and Final Processing

Prior to filtration, yeast and cold trub are removed from the beer. If a centrifuge is available, the yeast can be separated through centrifugal force before the beer undergoes final filtration. Alternatively, the beer can proceed directly to filtration.The entire low-temperature fermentation process, often referred to as single-tank fermentation, typically takes 23–28 days from inoculation to final filtration. This method combines primary fermentation and maturation in the same vessel, reducing the need for transferring the beer between tanks and thus minimizing contamination risks and labor requirements.

Advantages of Low-Temperature Fermentation

Low-temperature fermentation offers several benefits, making it a preferred method for many breweries:1. Enhanced Flavor Stability

The controlled fermentation conditions allow for a slower and more deliberate development of flavors, resulting in a clean, crisp, and well-rounded beer.

2. Improved Efficiency

By combining fermentation and maturation in a single conical fermenter, breweries can maximize their use of equipment and reduce operational costs.

3. Minimized Off-Flavors

The gradual temperature changes and controlled pressurization during fermentation significantly reduce the production of unwanted compounds such as diacetyl and higher alcohols.

4. Ease of Yeast Management

Conical fermenters simplify the process of yeast removal and harvesting, allowing for more efficient reuse of yeast in subsequent batches.

.jpg)

Tiantai Beer Equipment Co., Ltd.: Your Partner in Brewing Excellence

Breweries looking to implement the low-temperature fermentation process require high-quality conical fermenters and reliable brewing systems. Tiantai Beer Equipment Co., Ltd. specializes in providing complete brewing solutions tailored to meet the diverse needs of the beer industry.Tiantai’s fermenters are designed to meet the rigorous demands of modern brewing, ensuring precise temperature control, durability, and ease of use. The company’s comprehensive product lineup includes everything from brewhouses and fermenters to auxiliary systems, offering a one-stop solution for breweries of all sizes.

Why Choose Tiantai Equipment?

1. Precision EngineeringTiantai’s conical fermenters are built with advanced technology to ensure consistent and reliable performance. Their design incorporates precise temperature control systems, facilitating the low-temperature fermentation process described above.

2. Customizable Solutions

Tiantai understands that every brewery is unique. Their equipment can be customized to meet specific production capacities, process requirements, and space constraints.

3. Comprehensive Support

From initial consultation to installation and after-sales service, Tiantai provides comprehensive support to help breweries optimize their operations.

4. Proven Track Record

With years of experience in the industry, Tiantai has established itself as a trusted partner for breweries worldwide, offering innovative solutions that enhance both efficiency and beer quality.

Low-temperature fermentation is a time-tested method that combines tradition with modern technology to produce high-quality beer. By leveraging advanced conical fermenters and carefully controlling temperature and pressure, breweries can achieve consistent results while minimizing labor and operational costs.

Tiantai Beer Equipment Co., Ltd. stands ready to support breweries in adopting this efficient and effective process. With their state-of-the-art brewing systems and expertise in fermentation technology, Tiantai is an ideal partner for any brewery aiming to enhance its production capabilities and deliver exceptional beer to its customers.

For more information about Tiantai’s brewing solutions, visit their website or contact their team of experts.

This document provides a comprehensive overview of the low-temperature fermentation process and the equipment necessary for its successful implementation. Breweries looking to adopt this process can rely on Tiantai for world-class support and cutting-edge technology.

.jpg)

Get In Touch